Use Macros to Guarantee Test Consistency

- Guarantee Test Consistency

- Perform Multiple Background Tasks

- Manage External Devices

- FAST Batch Testing

- Easily Used by Unskilled Operators

- Supports Bar Code Readers

- Data Logging to Disk or Printer

The standard CableEye® software that's included with every tester offers out-of-the-box automation capabilites. By completely automating the test process after the operator attaches a cable, you eliminate any chance that testing or documentation will differ from one cable to the next.

Setup your test station to perform multiple background tasks, all triggered automatically with a single click of a button or the scan of a barcode. Easily control the workflow of your test with Macros, our built-in scripting language.

Control tower lights, locks, PLCs, counters, pistons or any other device for a continuous, high quality test workflow. API integration with other equipment or software is possible. LabVIEW and .NET libraries are available.

Use external relay boards (CB35) to manage external devices such as automatically switching different circuits in your UUT during test. Each CB35 board offers ten relay outputs and you can cascade as many boards as needed.

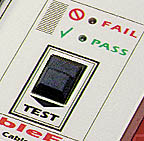

An entire test sequence you create can be automated for one-button (or single barcode scan) operation. Press the TEST button (illustrated below) to start a test procedure and see test results on LED lamps without referring to the computer screen. A typical test procedure consists of commands to the tester, illustrated in the Automatic Test window (shown below). Within the test sequence you may include display of wiring differences, searching the database, printing labels, and logging test results to an archival database.To trigger the test, you may also set up and press an icon on a touch screen computer, or connect a footswitch or other peripheral. If desired, build your own control unit with pushbutton and lamps and connect it to the REMOTE socket on the tester.

For production environments, we highly recommend you set up your tester to run in Production mode.

What to look for in a tester when creating a smart cable & harness assembly and test line, especially when following a mixed-model manufacturing process. Read now! Automation Demonstration

Easily control the workflow of your test with Macros, and use the options to control tower lights, LEDs, audible tones, labels, latches and more. Scan barcodes to initiate tests and input data. Click to watch.