Contents

OverviewTester Preparation: Standard Steps

M2/M3/M4 Series Guidelines

HVX Series Guidelines

Accessories Only Guidelines

Case Studies

Summary

Overview

These Guidelines help to define the phrase "Pack securely with adequate protective cushioning" stated in every Service Shipping Checklist. The checklists are accessed through each of our service pages and should be reviewed and circulated to your shipping department each time you ship your tester to us. It is important that you ensure every item on the Service Shipping Checklist has been completed.

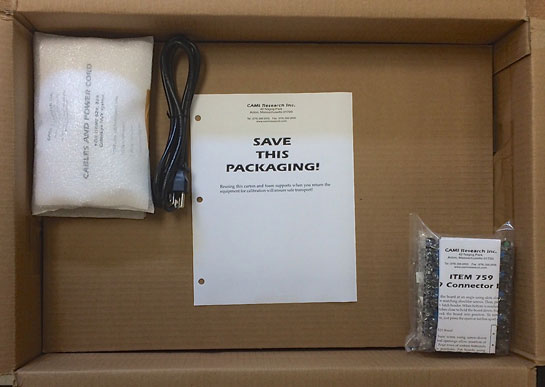

Inadequately packaged testers are the root cause of in-shipment damage noted on testers we receive at CAMI Research. Sadly, affixing "Handle with Care" labels to an inadequately packaged system will not ensure the safety of the tester. The cost in terms of repair costs and time delay are readily avoidable. Note that, effective 21 October 2020, every new tester ships in a carton clearly labeled with a recommendaton to save the packaging (carton +) for reuse when shipping the tester for service. If a separate department typically unpacks your deliveries, you may wish to reinforce this recommendation in advance of the tester arriving at your facility. For your convenience, the label includes a URL and QR code to link to this "Packaging Guidelines" page.

If you ordered a system with accessories, your box will be sized accordingly, and the accessories will lie above the tester. For most services, accessories should not be shipped back except for those explicitly called out on the Service Shipping Checklist and in the Tester Preparation panel below. When reusing the carton, your packing department will need to either back-fill this space, or fold down the box along the score lines to fit.

Tester Preparation: Standard Steps

- With the exception of module interlink cables (Fig. 1), disconnect all cables including probe and green ground wire.

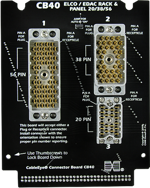

- Some HVX systems have cables as shown in Fig. 2 (annotated 1, 2, 3, 4). INCLUDE THESE DISCONNECTED CABLES with your shipment.

- Some HVX systems are fitted with a metal plate (approx. 3.6" x 8.5"). Remove this plate to disconnect the cables shown in Fig. 2. Do NOT ship the plate with the system.

Set of Four. - Disconnect and Include with Shipment

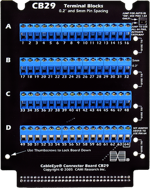

- Do not disconnect expansion modules, interlink boards (Fig. 3).

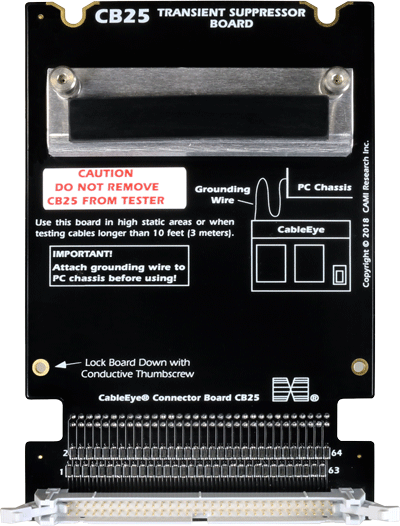

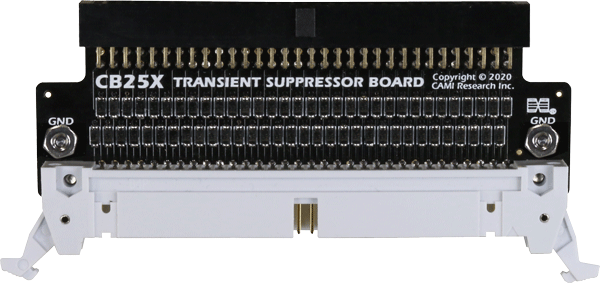

- Do not disconnect transient suppressor boards CB25, CB25X (Fig. 4). Applies only to M3U series testers.

Fig 4: CB25, CB25X

Applies only to M3U Series Testers!

Leave Attached

- INCLUDE POWER MODULE (not applicable to HVX-series testers).

- Do NOT ship any accessories (QuickMount™ housings, probe, USB cables, etc.) other than those described above! DO NOT SHIP YOUR TEST INTERFACE FIXTURES!

- Confirm all header connector tabs are in the open position (Fig. 5) and all toggle switches are in center/off position.

Fig 5: 'Open' (bottom), and 'Closed' (top) Header Connectors - Leave Open

- Complete the more detailed Service Shipping Checklist for the correct service (available through the appropriate Service page), and refer back to this page for an explanation of "Pack securely with adequate protective cushioning" following the benchmark that matches your configuration:

- Follow the highlighted preparation list above.

- Reuse the original packaging: carton, bubble wrap, biodegradable packing peanuts, foam.

- When original carton and packing peanuts are unavailable, use our optional Pelican carrying or carrying/rolling storage and transportation cases, or pull together a new carton and packing material as follows:

- You may substitute alternative padding material for the recommended packing peanuts. However, we do not recommend paper (rolled or otherwise) or Airpak-type products as they tend to shift during shipping leading to certain parts of the tester becoming more vulnerable to damage.

- Thickly wrap the tester in bubble wrap, covering all corners & connectors.

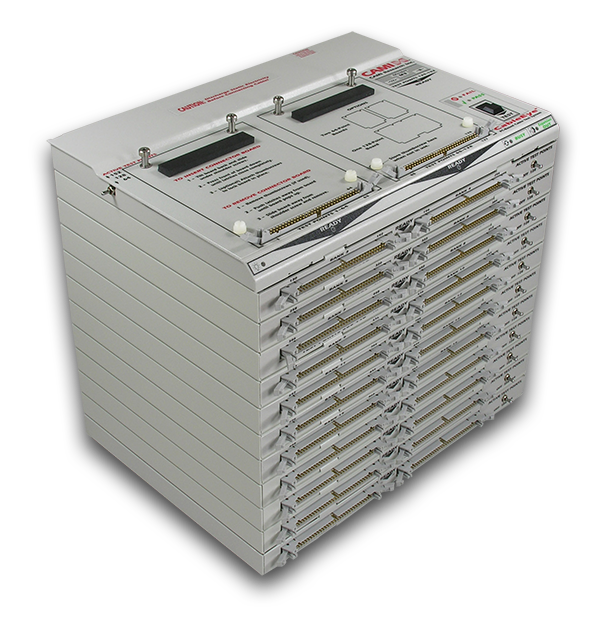

- Select a sturdy box. Choose a double-walled box for systems with 4 or more expansion modules.

- Be sure to select a large enough box to enclose the bubble-wrapped tester once the tester is surrounded with about 2" (5cm) of padding (see previous point for exclusions), ensuring that there is minimal movement of the tester within the padding in any direction.

- Fill the box to the sides and top with packing material. Do not leave any gaps. This will prevent the box & system from being crushed.

- When there are seven (7) or more expansion modules in the stack, use sheet foam to form the aforementioned 2" (5cm) of padding that surrounds the bubble-wrapped tester.

The following are photographic examples of the above packing guidelines.

Step 1

Complete the highlighted preparation list above then return to these instructions.

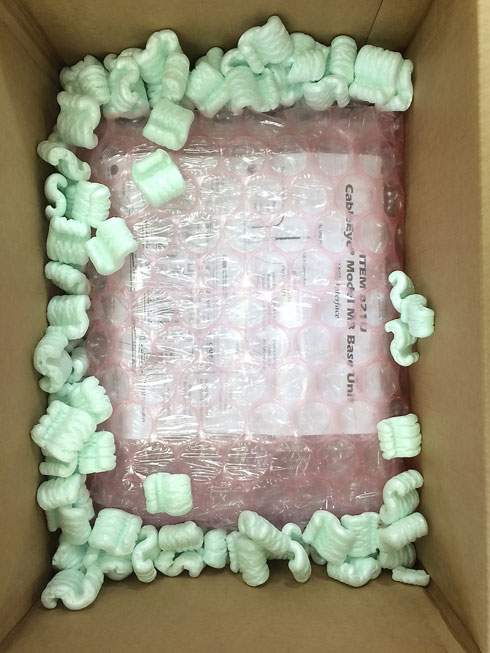

Place 2" of padding in base. Biodegradable packing peanuts are recommended. Do not use paper or Airpak-type products.

Step 2

Place thickly bubble-wrapped tester on base padding and FILL all gaps, including sides and top, with more padding. Biodegradable packing peanuts are recommended. Do not use paper or Airpak-type products. Do not leave any gaps. This will prevent the box and system from being crushed.

Complete the highlighted preparation list above then return to these instructions.

Place 2" thick sheet foam on the base.

Lay the thickly bubble-wrapped system on its back on the base foam and surround all other sides with more 2" thick sheet foam. FILL all gaps. This will prevent the box and system from being crushed.

Photo content Being Prepared.

Step 1

- Complete the highlighted preparation list above then return to these instructions.

- If your system has six or fewer expansion modules, loading front of tester first, lay the system right way up on the foam with the front of the tester towards the label on the case marked "front". The position of this label depends on which case you have.

- If your system has seven or more expansion modules, loading the top of the tester first, lay the stack on its back with the base of the stack towards the wheels.

Step 2

- Place power supply and cables in accessory pocket. If there is no accessory pocket (sixteen or more expansion modules) package them separately.

- Confirm flashdrive is inside.

- Close the case, lift by handle/s and confirm the tester does not shift inside the case (add foam if needed).

- For yellow Pelican cases, secure padlock hasps with cable ties.

- Black or tan briefcase style cases should be left unlocked, and placed inside a carton.

Click for Next Topic in M2/M3/M4 Packaging Guidelines : Case Studies

A printable version of the guidelines for you to distribute to your shipping department.

Print now!

- Use the original packaging, especially the form-fitted foam.

- Complete the highlighted preparation list above then return to these instructions.

- When original carton and packing peanuts are unavailable, use our optional Pelican carrying/rolling storage and transportation cases, or pull together a new carton and packing material as follows:

- We do not recommend paper (rolled or otherwise) or Airpak-type products as they tend to shift during shipping leading to certain parts of the tester becoming more vulnerable to damage.

- Wrap the tester in bubble wrap, covering all corners & connectors.

- Be sure to select a double-walled box that is large enough to enclose the bubble-wrapped tester once the tester is surrounded with about 2" (5cm) of sheet foam, ensuring that there is minimal movement of the tester within the foam in any direction.

- Fill the box to the sides and top with packing material. Do not leave any gaps. This will prevent the box & system from being crushed.

"HVX Packaging Guidelines" (PDF)

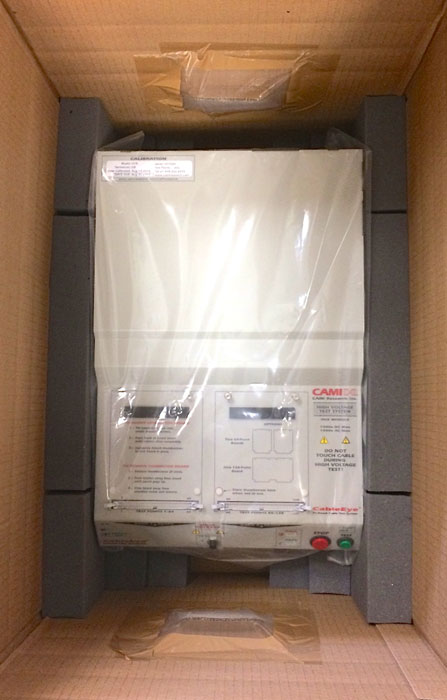

The following are photographic examples of the HVX packing guidelines.

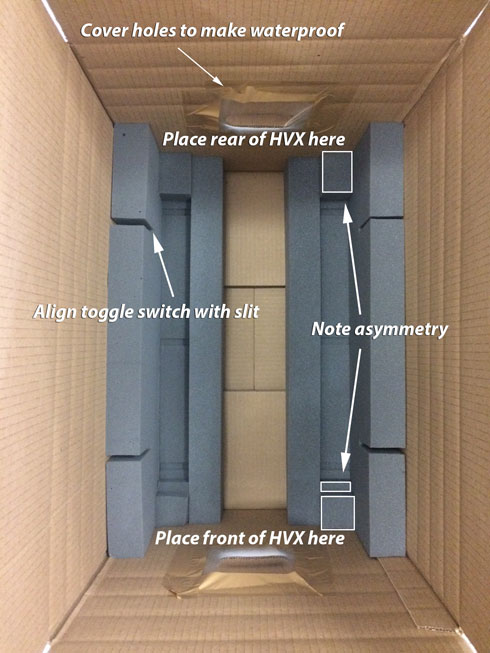

Step 1

- Complete the highlighted preparation list above then return to these instructions.

- Place two largest pieces of form-fitting foam in base.

Step 2

Place plastic-wrapped HVX on base foam.

Step 3

Note orientation of two remaining pieces of form-fitting foam.

Step 4

Place two remaining foam pieces as shown.

Step 1

- Complete the highlighted preparation list above then return to these instructions.

- Loading the front of the tester first, lay the system right way up on the foam with the back of the tester towards the wheels.

Step 2

- If your unit was issued with a CAMI-branded credit card-sized flashcard, confirm it is inside the case.

- Secure padlock hasps with cable ties.

Step 3

- Pack and ship interstack cables separately (Fig. 2).

Next Topic : Case Studies

A printable version of the guidelines for you to distribute to your shipping department. Print now!

- If you are shipping accessories for Repair Service with a tester that is being returned for service (Calibration, Repair, or Upgrade), please follow the instructions for the tester service (available through the appropriate Service page). Otherwise, follow the Repair Service Shipping Checklist, and refer to this page for an explanation of "Pack securely with adequate protective cushioning".

- Bubble wrap each accessory individually, covering all corners and connectors, and place in box.

- Fill the box to the top with packing material (bubble wrap/peanuts). Do not leave any gaps. This will help prevent the box & accessory from being crushed.

Inadequate Packaging

Dropped Box (HVX)

The carrier dropped this shipment. The box was neither double-walled nor packed adequately. You can see a) evidence the non-double-walled box was crushed, b) indents the unprotected toggle switch made in the cardboard, and c) damage to the tester. The repair cost was significant.

Improper & Careless Packing (M3)

The box was not packed adequately. You can see a) incorrect packing material type, b) inadequate padding resulting in the tester being able to move/shift significantly within the carton, c) careless placement of the tester (placed upside-down!), d) evidence airpaks were pierced & deflated, and e) indents the unprotected headers made in the cardboard. Compare this case with the next.

International Shipment (M3 with 4 Exp. Modules)

This international customer no longer had the original packing materials and did an excellent job pulling together new materials and packing the tester. Note that the box was topped off with foam.

Summary

Previous Topic | M2/M3/M4 Guidelines | HVX Guidelines |TOC

| Follow Appropriate Service Shipping Checklist | All Models | Comments | |

|---|---|---|---|

| Select one: | |||

| Original carton/packaging | ✔ |

||

| Double-walled carton | ✔ |

Any sturdy carton is acceptable for M-series testers with ≤ 6 expansion modules. | |

| Transportation Case | ✔ |

||

| Complete all: | |||

Disconnect cables |

✔ |

Except for interlinks. | |

Do not disconnect expansion modules or, for M3U series only, CB25, CB25X. |

✔ |

Remove all other accessories. DO NOT SHIP YOUR TEST INTERFACE FIXTURES. | |

Include power module |

✔ |

Not applicable to HVX series. | |

Leave header connector tabs 'open' and all toggle switches in center/off position |

✔ |

||

Bubble wrap - include corners & connectors |

✔ |

Not needed if original form-fitted foam is used. | |

2" padding all around |

✔ |

Do not use paper or Airpak-type padding/fillers. | |

Completely fill box |

✔ |

||

| DO NOT USE A CRATE OR PALLET! | |||

CAMI Research Inc.

42 Nagog Park, Suite 115

Acton, MA 01720

Tel: (978) 266-2655

e-mail: supportREMOVE@REMOVEcamiresearch.REMOVEcom

If you have technical or other questions, please contact Technical Support at the above numbers, or chat with us live by clicking on 'Live Chat' below.