CAMI Research and Doyle Manufacturing Announce Integration Partnership Providing Low Insertion Force, Plug and Play, CableEye Test Interface Fixtures

Oct 7, 2019

CAMI Research Inc. (Acton, MA) and Doyle Manufacturing Inc. (Bristol, IN), have joined forces to offer the design and manufacture of low insertion force, CableEye ® test interface fixtures providing CableEye users with full plug and play solutions – mapped, electrically tested, and ready to use.

The Partners

CAMI manufactures the CableEye*#8239;® highly versatile, expandable and upgradable, diagnostic and Pass/Fail check Cable and Harness Test System that’s PC-based. It’s used for assembly, prototyping, production, and QC of standard or custom wire cables and harnesses in countless applications such as Transportation, Energy, Medical Devices, Defense, Scientific R&D, Telecom, and more. The first CableEye tester was sold twenty-six years ago, and systems are now installed in thousands of locations around the world.

Doyle is a custom machine shop specializing in pogo pin test plugs, production connectors, and continuity testing fixtures. The products can be found on assembly lines and test stations across USA, Canada, and Mexico. Doyle has been serving the industry since 1989.

The Technology

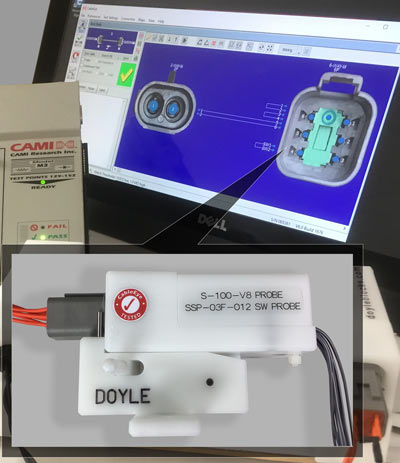

Testing continuity and quality of connections through to wire twist relationships and insulation quality, CableEye testers are very flexible systems offering a plethora of test interface fixture attachment strategies. CAMI sells standard and custom plug in boards, and offers a service for designing and building custom interface fixtures that frequently differ in form and fit from the standard plug in boards. All interface fixtures delivered by CAMI are designed to be auto-detected, plug and play devices for fast, convenient set-up and testing of any cable or wire harness. Built-in diagnostic tools enable the user to instantly see a schematic of the wiring and connectors under test on their computer screen.

CableEye testers are increidbly versatile and are expandable to accommodate large and complex harnesses; users can connect and configure them in numerous ways — set up an array of QuickMount™ housings fitted with connector boards, plug custom interface cables directly into any of the 64 pin headers on the control and expansion modules, or use a test interface panel, perhaps on a rack-mounted system. Not just a tester, a CableEye tester is a complete cable management system offering features not available on any other cable test equipment, and will adapt to virtually any connector.

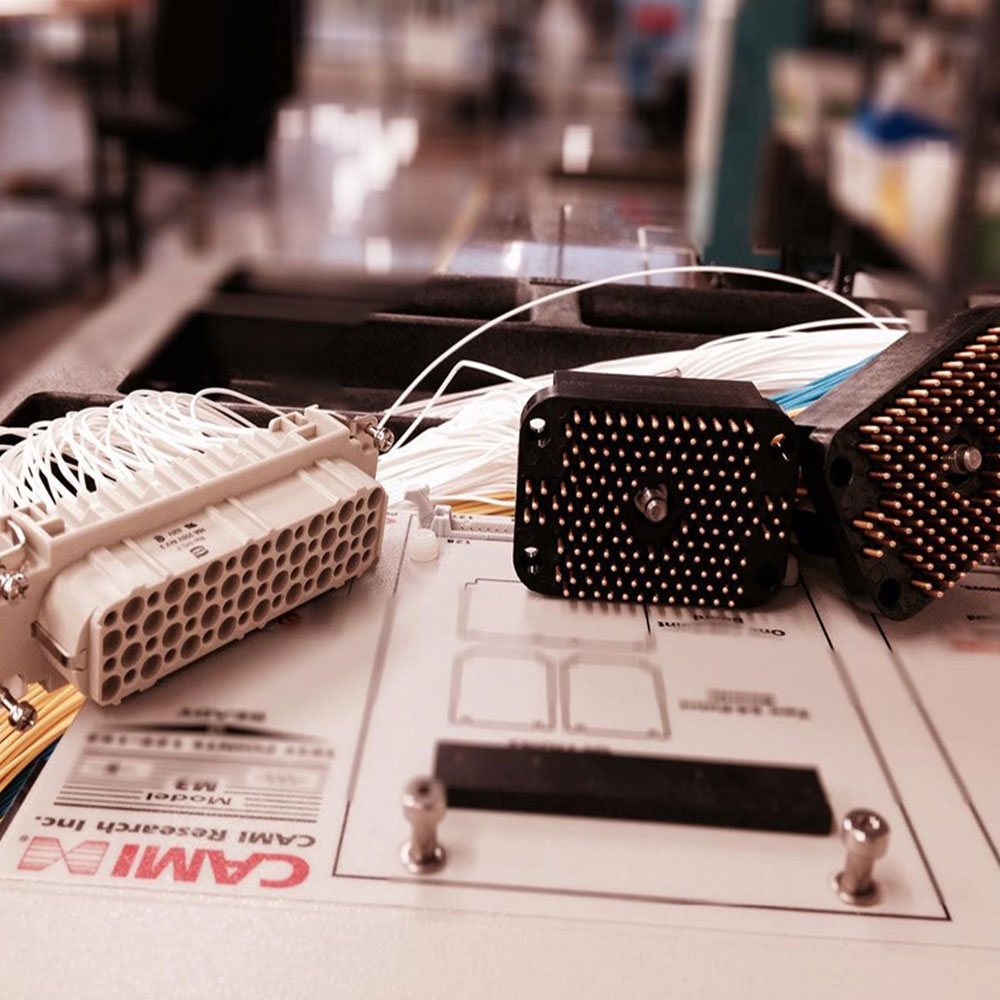

Doyle’s core competency aligns perfectly with the need for low insertion force, plug and play, CableEye test interface fixtures. Doyle blocks are CNC machined for the highest quality and accuracy and are available with a range of functionality: Pneumatic release lock blocks and electric solenoid release lock blocks for quality assurance; part presence detection for secondary locks, clips, etc.; and step probes and push back switch probes for checking properly seated terminals. All of these block functions can be monitored and controlled by CableEye software out-of-the-box automation capabilities and, if desired, may be supplemented with audible tones, visual tower lights and more. API integration with other equipment is also possible – LabVIEW and .NET libraries are available.

The Partnership

Effective immediately, Doyle will begin offering value added services to users of CableEye testers, providing design and manufacture of single or multi-block panels that are 100% electrically tested by a CableEye tester and include a detailed test report. CableEye connector graphics files will be generated and included (for those connectors not already in the CableEye connector library) for professional quality graphic display of connectors and cables. Every pin in each block will be wired, permitting comprehensive troubleshooting (such as checking for all possible miswires) while making the block reusable with different harnesses using the same connector. Panels will ship with 64-pin headers and a custom CableEye pin map for auto-detect, plug and play operation. Customers can purchase an appropriate cable from CAMI Research to connect the panel to their tester (ribbon up to 500V, AMPMODU™ above 500V).

This service will appeal to any CableEye system user with a need for low insertion force, plug and play test interface fixtures whether as a single block or a panel of many blocks, and especially to those customers who lack the time or skillset to design and manufacture their own. The markets for this service will be typically automotive and medical.

“It is my pleasure to announce that CableEye system users can now contact Doyle Manufacturing to develop low insertion loss, plug and play, test interface solutions for their production environment. This partnership offers strong support for our businesses,“ said Christopher Strangio, President of CAMI Research Inc.

“The versatility of the CableEye system is impressive. We are excited to partner with CAMI Research and provide custom, user friendly, pogo pin test fixtures for CableEye system users. I see this as a win for all parties,” said Myron Miller, President of Doyle Manufacturing Inc.

Availability & Domestic US Pricing

Available immediately, CableEye tester-ready, low insertion force, test interface blocks start at $120 plus service fee. Contact doylemfg@doyleblocks.com or +1 (574) 848-5624 for a quote.

All CableEye test systems are automation-ready and start at $1,295. Contact salesREMOVE@REMOVEcamiresearch.REMOVEcom or +1 (978) 266-2655 for a quote.

Note: Prices are USA only and subject to exchange rates, freight and import costs. Contact your local authorized distributor for local pricing.

CAMI Research produces expandable and upgradable diagnostic Cable & Harness Test Systems for assembly, prototyping, production, and QC of standard or custom cables. CableEye ® Testers display, and document electrical properties such as continuity, resistance, capacitance, dielectric breakdown, insulation resistance, miswires, and intermittent defects.

CableEye ® Automation-Ready Cable and Wire Harness Test Systems

CableEye testers are highly versatile, expandable and upgradable diagnostic and Pass/Fail check Cable and Harness Test Systems that are PC-based. They are used for assembly, prototyping, production, and QC of standard or custom wire cables and harnesses The entire suite of products is powered by the same easy-to-use operating software and, with the help of its signature easy-to-interpret color-coded graphics, instantly identifies not only when there is a fault, but what type of fault and where.

Low Voltage M2 Series

For diagnostic and Pass/Fail Testing - Find, display, log, & document continuity (opens, shorts, miswires, intermittent connections).

Low Voltage M3 Series

For all of the above plus resistance (contact, isolation, embedded), and diodes (orientation, forward voltage, reverse breakdown).

Low Voltage M4 Series

For all of the above plus precision resistance (4-wire), and capacitance (twist wire relationship, length of cable, length to break, capacitors).

Low Voltage and High Voltage HVX Series

For all as described for M3 plus HiPot (dielectric withstand voltage and insulation resistance). 4-Wire Kelvin Measurement and Advanced Measurement Options (capacitance, twist wire relationship, length of cable, length to break, capacitors) are available.

Try One!

photo credit: Progressive Image

photo credit: AP Technology

"Our production guys find it simple to setup and use. Our clients love it as it provides complete traceability for each and every cable assembly we manufacture."

AP Technology, UK