CAMI Celebrates 25 Years Developing Automation-Ready Cable and Harness Testers

September 7, 2018

CAMI Research Inc. (Acton, MA), manufacturer of the CableEye® automation-ready cable and harness test system, is marking 25 years since its first sale and of innovating highly configurable test solutions for simple and complex multiconductor cables and harnesses. Trusted by industry leaders such as CERN, Ford, GE, Hitachi, NASA, Abbott, TESLA, Lockheed Martin, Raytheon, Airborn, Furukawa, TE Connectivity, and the Nobel prize-winning group, LIGO, thousands of test systems have shipped globally over the years.

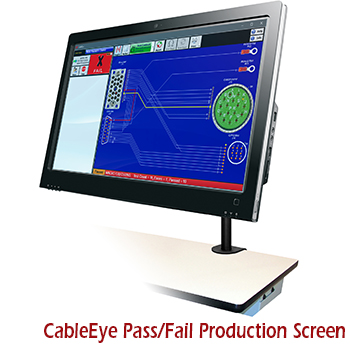

The founder's vision for CAMI Research involved developing a suite of pc-based cable testing products powered by the same intuitive software that, with the help of easy-to-interpret color-coded graphics, instantly identifies not only when there is a fault, but what type of fault and where (Fig. 1). The CableEye brand's highly configurable nature and automation-readiness is directly attributable to this advanced software.

Initially released for DOS in 1993 and updated regularly to work with the latest operating systems, The CableEye brand of cable testers is currently compatible with computers running all modern Windows operating systems. Test engineers and managers are free to choose any size monitor they require, including Touch Screens and all-in-one computers.

Of course, development of robust and modular hardware has taken major effort too, all leading towards a system that can be used automated or not, as a pass/fail check tester, or a diagnostic system at the whim of the owner.

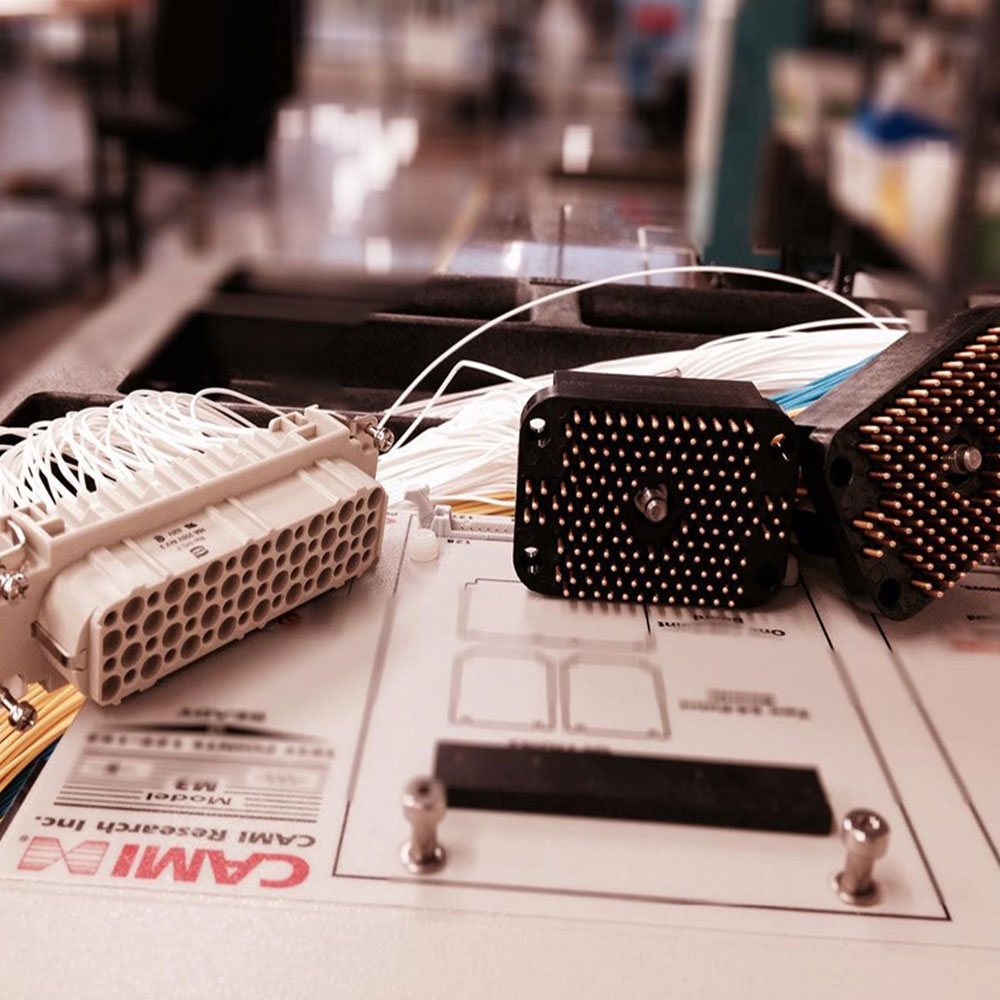

Following release of their first product, which was a low voltage tester with fixed test connectors, CAMI switched to an industry-standard 64-pin header interface and developed easily-interchangeable, auto-detected, test interface fixtures known as connector boards. The software automatically displays a clear graphic of the connectors and wiring under test and the tester can be readily programmed to do the same for custom boards and fixtures using the PinMap™ fixture editor option that was released in 1993. Connector Designer™ connector editor (2000) is an option that allows creation of custom graphics for unusual connectors (e.g. connectorized catheters) not found in the graphics library. With a single click, the wiring schematic (see photo) can be switched to a customizable netlist view. In both views, a large PASS/FAIL indicator is clearly visible. The stackable CB35 relay board, with 10 digital outputs per board, is a popular choice for those who need to manage external devices for full control and automation of the test station.

CAMI Research released its first HiPot tester, the HVX, in 2009. In 2015, the HVX-21 was launched that increased the maximum test voltage from 1500Vdc to 2100Vdc. There are now seven tester models covering low voltage and HiPot requirements, the most recent of which was released this year adding the capability of checking twist pair relationships. Autobuild™ guided connector assembly is a software option that was released in 2006 and which was augmented in 2008 by the release of the LightDirector™ light-guided connector assembly accessory.

The CableEye PC-based Continuity and HiPot test system is a professional test instrument used to pass/fail check and diagnose multiconductor cables found in countless applications in Transportation, Aerospace, Energy, Appliances, Medical Devices, Defense, Robotics, Telecommunications, Scientific R&D and more. CableEye takes full advantage of the PC's color graphic display, high-speed computation, and mass storage to provide a complete cable and wire harness management system.

Availability & Domestic US Pricing

Contact salesREMOVE@REMOVEcamiresearch.REMOVEcom or +1 (978) 266-2655 for a quote. Systems start at $1,295.

Note: Prices are USA only and subject to exchange rates, freight and import costs. Contact your local authorized distributor for local pricing.

CAMI Research produces expandable and upgradable diagnostic Cable & Harness Test Systems for assembly, prototyping, production, and QC of standard or custom cables. CableEye ® Testers display, and document electrical properties such as continuity, resistance, capacitance, dielectric breakdown, insulation resistance, miswires, and intermittent defects.

CableEye ® Automation-Ready Cable and Wire Harness Test Systems

CableEye testers are highly versatile, expandable and upgradable diagnostic and Pass/Fail check Cable and Harness Test Systems that are PC-based. They are used for assembly, prototyping, production, and QC of standard or custom wire cables and harnesses The entire suite of products is powered by the same easy-to-use operating software and, with the help of its signature easy-to-interpret color-coded graphics, instantly identifies not only when there is a fault, but what type of fault and where.

Low Voltage M2 Series

For diagnostic and Pass/Fail Testing - Find, display, log, & document continuity (opens, shorts, miswires, intermittent connections).

Low Voltage M3 Series

For all of the above plus resistance (contact, isolation, embedded), and diodes (orientation, forward voltage, reverse breakdown).

Low Voltage M4 Series

For all of the above plus precision resistance (4-wire), and capacitance (twist wire relationship, length of cable, length to break, capacitors).

Low Voltage and High Voltage HVX Series

For all as described for M3 plus HiPot (dielectric withstand voltage and insulation resistance). 4-Wire Kelvin Measurement and Advanced Measurement Options (capacitance, twist wire relationship, length of cable, length to break, capacitors) are available.

Try One!

photo credit: Progressive Image

photo credit: AP Technology

"Our production guys find it simple to setup and use. Our clients love it as it provides complete traceability for each and every cable assembly we manufacture."

AP Technology, UK