Five Qs to ask when selecting a Cable and Harness Tester

Is it PC-Based?

A PC-Based system is operated by an autonomous (rather than embedded) computer. Being independent of embedded computer architecture, the hardware is more robust, easier to upgrade, and has a longer life-cycle. Companies that require a flexible versatile test system, with dynamic graphic-rich GUI, archival data-logging, and ISO9000 quality documentation typically need to choose PC-based systems.

Is it expandable?

Look at least five years ahead to estimate how many test points you might ultimately need to have to test, and make sure that the tester you buy today is expandable - with ease. To avoid bench-top-creep, look for a system that stacks as it expands. For optimal versatility, and minimal operator retraining, check that the same system can be used to test either single cables or harnesses, and that if you ever need to add HiPot testing that the GUI is identical. Also, make sure that the system supports infinite connector types through numerous graphic templates - you don’t want to be caught short with your next series of product releases - and that you have a choice of a wide range of standard connector boards. It would also be helpful for you to know that the the tester supplier can support you with custom interface boards and adapters should the need arise.

Is there a mode for real-time screening for intermittent connections? At what rate?

Testing is incomplete without testing for intermittent errors: a cable can pass continuity testing, yet fail intermittence testing. This same cable, if installed, could cause a critical failure - perhaps resulting in loss of life. Testing for intermittent errors is carried out using a continuous rapid stream of short test pulses … each one sweeping through the full set of test points. Known sometimes as the ‘continuous’ test, the test signal itself is sometimes mistakenly believed to be continuous. The higher the pulse rate, the more accurate the result as there is a higher statistical likelihood of ‘capturing’ the random moment of error. Testers that offer an intermittence test mode but at a slow rate will pass cables that fail on systems with high rates. Testers with the highest rates (and therefore most accurate results) will have USB interfaces. Some testers allow this rate to be adjustable, and can be set as fast as 11ms/cycle.

Does it permit automation scripting? In a simple, intuitive language? And enable pop-up work instructions?

If your operators are performing repetitive multistep tests on your cables, you’ll want to automate the steps to improve productivity, and reduce operator error. Ideally, your tester will allow a simple, intuitive language option for you to prepare these scripts with no previous programming skills. These same testers will provide a shortcut icon on the touch screen leading the operator only to the test at hand and the features required for that test. They’ll also let you display a pop-up window with work instructions containing text, photos, interactive buttons, and triggers to open additional resources such as video, schematics, parts lists and BOMs.

How flexible is tolerancing?

For greatest flexibility, and more intelligible reports, check whether the system allows tolerances to be optionally defined as % or absolute terms, as well as asymmetrically (e.g. +0%/-10%). Asymmetric tolerancing will allow you to pass more product than using more constrained test parameters (e.g. +10%/-10%).

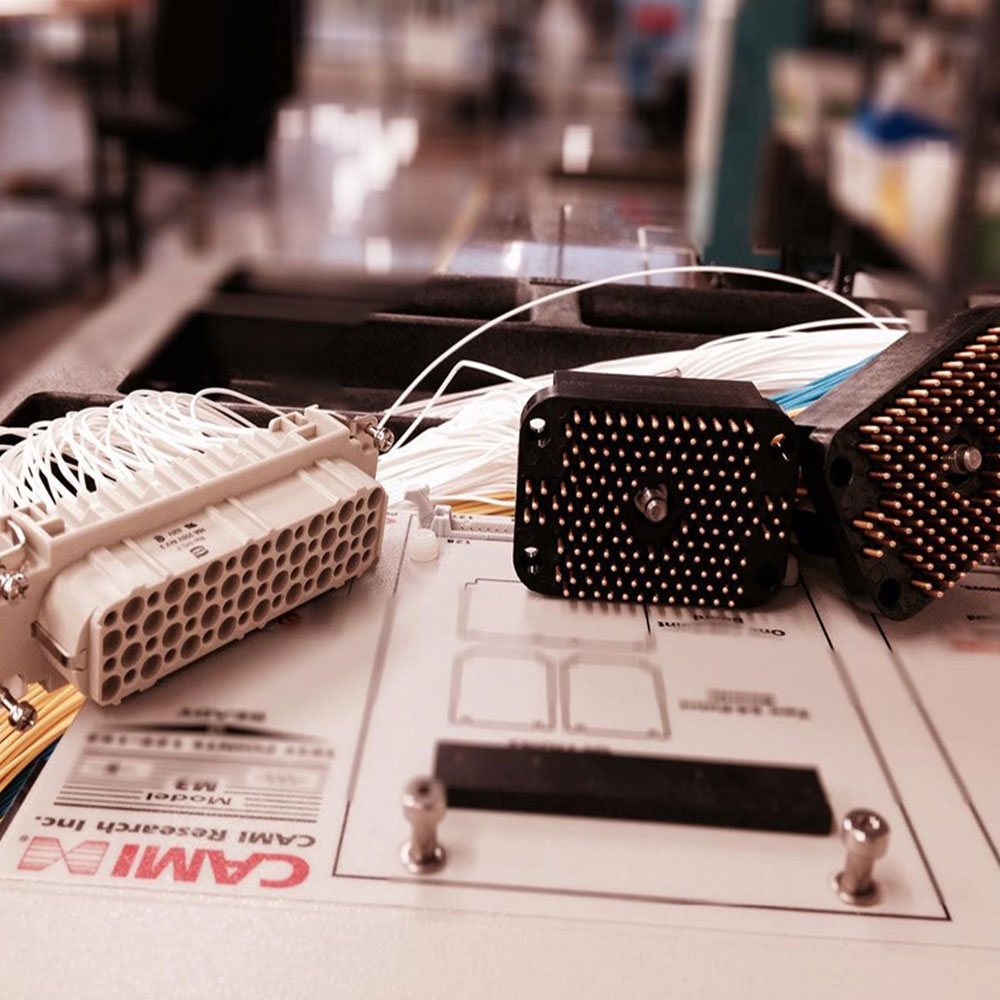

CableEye ® Automation-Ready Cable and Wire Harness Test Systems

CableEye testers are highly versatile, expandable and upgradable diagnostic and Pass/Fail check Cable and Harness Test Systems that are PC-based. They are used for assembly, prototyping, production, and QC of standard or custom wire cables and harnesses The entire suite of products is powered by the same easy-to-use operating software and, with the help of its signature easy-to-interpret color-coded graphics, instantly identifies not only when there is a fault, but what type of fault and where.

Low Voltage M2 Series

For diagnostic and Pass/Fail Testing - Find, display, log, & document continuity (opens, shorts, miswires, intermittent connections).

Low Voltage M3 Series

For all of the above plus resistance (contact, isolation, embedded), and diodes (orientation, forward voltage, reverse breakdown).

Low Voltage M4 Series

For all of the above plus precision resistance (4-wire), and capacitance (twist wire relationship, length of cable, length to break, capacitors).

Low Voltage and High Voltage HVX Series

For all as described for M3 plus HiPot (dielectric withstand voltage and insulation resistance). 4-Wire Kelvin Measurement and Advanced Measurement Options (capacitance, twist wire relationship, length of cable, length to break, capacitors) are available.

Try One!

photo credit: Progressive Image

photo credit: AP Technology

"Our production guys find it simple to setup and use. Our clients love it as it provides complete traceability for each and every cable assembly we manufacture."

AP Technology, UK