Cable and Harness Manufacturing:

CableEye® Cable Test and Management System, Q&A

What is a CableEye® cable tester?

CableEye is a brand of expandable and upgradable diagnostic and Pass/Fail Cable and Harness Test System that’s PC-based. It’s used for assembly, prototyping, production, and QC of standard or custom wire cables and harnesses.

Each of our models instantly measures, displays, and documents basic electrical properties. Both HiPot models, for example, can test resistance, dielectric breakdown, insulation resistance, miswires, and sporadic defects.

Most significantly, it’s a system that can reliably improve productivity, product quality, and documentation … with rapid ROI. Because it’s backwards compatible for all system hardware and software upgrades, handles extensive product complexity, and has a comprehensive test portfolio, it ensures usability, and thus investment longevity, across product lines, lifecycles, and generations - so it remains relevant as our customer’s product design changes.

We've several customers still using 15 year and older CableEye systems because they've been able to keep them relevant merely by installing software updates. Current CableEye test system software can operate all models dating back to the very first manufactured in 1993, and run on any PC operating system from DOS, through basic Windows, to the latest Windows release.

What are the alternatives to the CableEye brand and how do they compare?

There are three categories of test systems on the market: PC-based (external control), microprocessor control, embedded PC (E-PC) control … from $1,300, $1,000, and $4,700 respectively. As you can see, the price of an E-PC system is significantly more than a PC-based system even after adding in the price of a computer. At these price points, more functionality like automation scripting, file management, and a dynamic graphical user interface is included with PC-based systems than with the others, with microprocessor controlled systems having the least.

A PC-based system not only tests cables, but also provides an integrated software package for cable design, labeling, documentation, cataloging, data logging, on-line assembly checking, and test scripting. It supports elimination of errors in transcription, drawing, and rekeying of wire lists as cables pass through design, test, and documentation phases. The user interface capitalizes on the presence of a full color computer display, even to the extent of optional touch screen operation.

A CableEye tester distinguishes itself from microprocessor and E-PC controlled systems in that not only does it have expandable and upgradable capabilities, but it also remains backwards compatible for all system hardware and software upgrades. This means it has the greatest investment longevity, because the equipment itself, test fixtures, data-acquisition electronics, connector cards, and the procedures and processes into which the system becomes embedded, all remain viable.

While the modern trend is towards PC-based systems, the largest volume of cable and harness equipment sold today is microprocessor-controlled. As they’re not PC-based, they can’t be upgraded. A popular tester design employed by several manufacturers uses a cigar-box-shaped chassis with assembly-language-driven embedded microprocessor control, rocker-switch pushbuttons, and an LCD character display. While some PC software is offered to link these testers to a PC, the software is optional and provides little more that cable file storage.

Although CableEye PC-based systems are similar to microprocessor systems in that they offer a small bench footprint and ease-of-use, one-button automatic test sequences well-suited for production line testing, they differ in that PC-based systems also offer a dynamically searchable database, documentation, and data logging capabilities needed for ISO9000-certified companies, and design, diagnostic, and assembly capabilities … so may be used beyond the production line right across the workflow.

Several standalone models are available that use E-PC control. Like the microprocessor systems, these also tend to have cigar-box-shaped chassis. While an external keyboard and monitor can be connected, these systems were designed for use with an on-board touch screen display and are more like an EM tester than like a PC-based system. By designing a PC-controller into the tester, these companies add significant hardware complexity (and some system functionality) to the tester which results in:

- considerably increased cost to the purchaser (by at least 50%),

- reduced reliability due to a greater number of components and thus an increased likelihood of failure.

- higher repair cost should the system require maintenance.

- more challenging (costly) h/w and s/w upgrading.

Who benefits from using the system?

Companies who produce or integrate cables and harnesses in their products, or who test/repair their own (or other’s) capital equipment that incorporates cables or harnesses.

Employees across the workflow at the above companies in the areas of design, assembly, prototyping, piloting, production, QC, and shipping from engineers to technicians and managers to production line workers.

Really anyone who has an interest in:

- improving quality and productivity

- flexible, comprehensive or pass/fail testing

- a system platform that, as time passes, remains relevant across the workflow as their products change.

How does cable and harness testing with a CableEye test system increase productivity?

We can see that a test system as flexible as a CableEye tester encourages productivity at each workstation and across the workflow. At the workstation level, it can be set up to be as complex as required for design and diagnostics, or as simple as required for automated pass/fail testing. Yet, significantly, there remains a common look and feel at each workstation level, allowing staff to become productive quickly as they switch between product lines, products, or between job function levels. So, as the product line changes and grows, the system can adapt in concert. Different types of test systems are not required at each stage of the workflow, resulting in minimal cross training. Even when switching, for example, from a low voltage product line to a HiPot product line, operators need little retraining, as the flexible test system HiPot hardware and software have a very similar look and feel. Empowered by a common system platform (across workflow and product lines), managers and supervisors enjoy being able to reassign operators with ease and confidence when faced with day-to-day staffing issues such as unexpected absences.

A CableEye tester facilitates increased productivity of quality, ready-to-ship products by encouraging error detection and resolution as upstream as can be designed-in to a manufacturing process. Error detection and correction is far more complex and time consuming if testing is only performed on a fully integrated system or product.

Clearly, down-time of revenue-generating cabled or harnessed capital equipment can be minimized by accurate identification and diagnosis of failed cables.

Can all cables/connectors be tested with the test system, or are there specific types for which it is intended?

CableEye cable and harness test systems are unlimited by connector type (or whether connectors are present at all), and address applications with long cables or no cables (e.g. backplane, PCB).

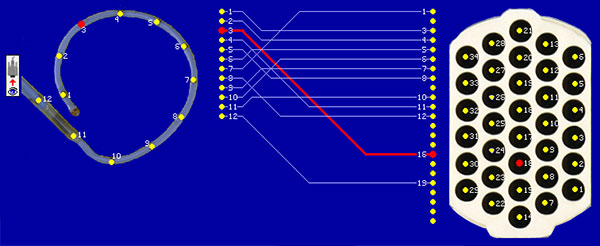

All CableEye systems come with software that includes over 500 connector graphics, and enough dynamic templates that users can automatically generate graphic images of many standard connector shapes with the needed pin count for use in custom cable designs and printed reports. And then our optional Connector Designer™ software, lets users design with unlimited shapes of connectors. They can even import a photograph for connector design manipulation. One of our more unique solutions, is the design of a connectorized catheter.

Screenshot shows the use of the custom graphics in test mode.

Our system is also supported by a growing, extensive library of about 60 connector boards, most of which are populated with 'families' of connectors such as the audio market CB19.

You may mix and match these boards in whatever combination you require to test a cable, and the system will automatically select and display the correct connector graphic.

There are options for testing unusual connectors or connector combinations such as mounting them on our unpopulated CB8 or CB29 boards, or working with us to customize their own board. To test harnesses, depending on the size, our users (a) build a mating harness, (b) construct a panel with all of connectors present, (c) build "pigtail" cables, or (d) mount mating connectors on the CB8 custom interface board. All connectors and pins can be custom labelled with our PinMap™ fixture editor software.

How much time can be saved by using a CableEye tester? How much more productive will a user be with the system?

A CableEye tester is so simple to use, that most people have the hardware connected, the software installed, and begin testing within about 10 minutes. It’s ‘plug and play’. And customers report amazing increases in productivity. They’ve measured production time reduction in just the first few hours of use. All our models are USB certified yielding fast test times. Low voltage tests performed by unexpanded control modules are literally faster than the blink of an eye.

Before proceeding to test, connectors not already existing in the connector library must be one-time mapped to the tester headers. Mapping the pins of complex and customized connectors, test fixtures or such, is a breeze with the PinMap™ fixture editor. Audible-tone-prompted, the user remains focused on the pins, rapidly probing the full set. No key entry is required - the PinMap software automatically generates a true, rather than generic, visual representation - a user-friendly visual that is easy, and therefore quick, to interpret.

For assembling complex or mission-critical connectors, we recommend our Light-Director™ guided assembly accessory. Assemblers can anticipate being able to roughly double their assembly rate over that of manual assembly … they experience near zero assembly errors, and less personal fatigue. CableEye testers are designed in such a way that the same equipment used for assembly can be used for testing, so there is no loss of time in moving the assembled piece to another workstation for testing. Feedback on the quality of assembled work is immediate.

Basically, the graphical user interface with its dynamic graphics and net list contributes to faster and more accurate design, assembly, test, and diagnosis, the result of which is improved productivity.

To learn more about the software that drives the tester referenced in this artcle, click the button below.

CableEye ® Automation-Ready Cable and Wire Harness Test Systems

CableEye testers are highly versatile, expandable and upgradable diagnostic and Pass/Fail check Cable and Harness Test Systems that are PC-based. They are used for assembly, prototyping, production, and QC of standard or custom wire cables and harnesses The entire suite of products is powered by the same easy-to-use operating software and, with the help of its signature easy-to-interpret color-coded graphics, instantly identifies not only when there is a fault, but what type of fault and where.

Low Voltage M2 Series

For diagnostic and Pass/Fail Testing - Find, display, log, & document continuity (opens, shorts, miswires, intermittent connections).

Low Voltage M3 Series

For all of the above plus resistance (contact, isolation, embedded), and diodes (orientation, forward voltage, reverse breakdown).

Low Voltage M4 Series

For all of the above plus precision resistance (4-wire), and capacitance (twist wire relationship, length of cable, length to break, capacitors).

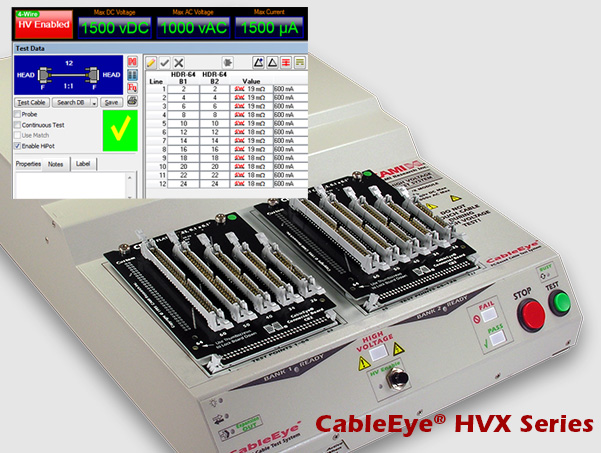

Low Voltage and High Voltage HVX Series

For all as described for M3 plus HiPot (dielectric withstand voltage and insulation resistance). 4-Wire Kelvin Measurement and Advanced Measurement Options (capacitance, twist wire relationship, length of cable, length to break, capacitors) are available.

Try One!

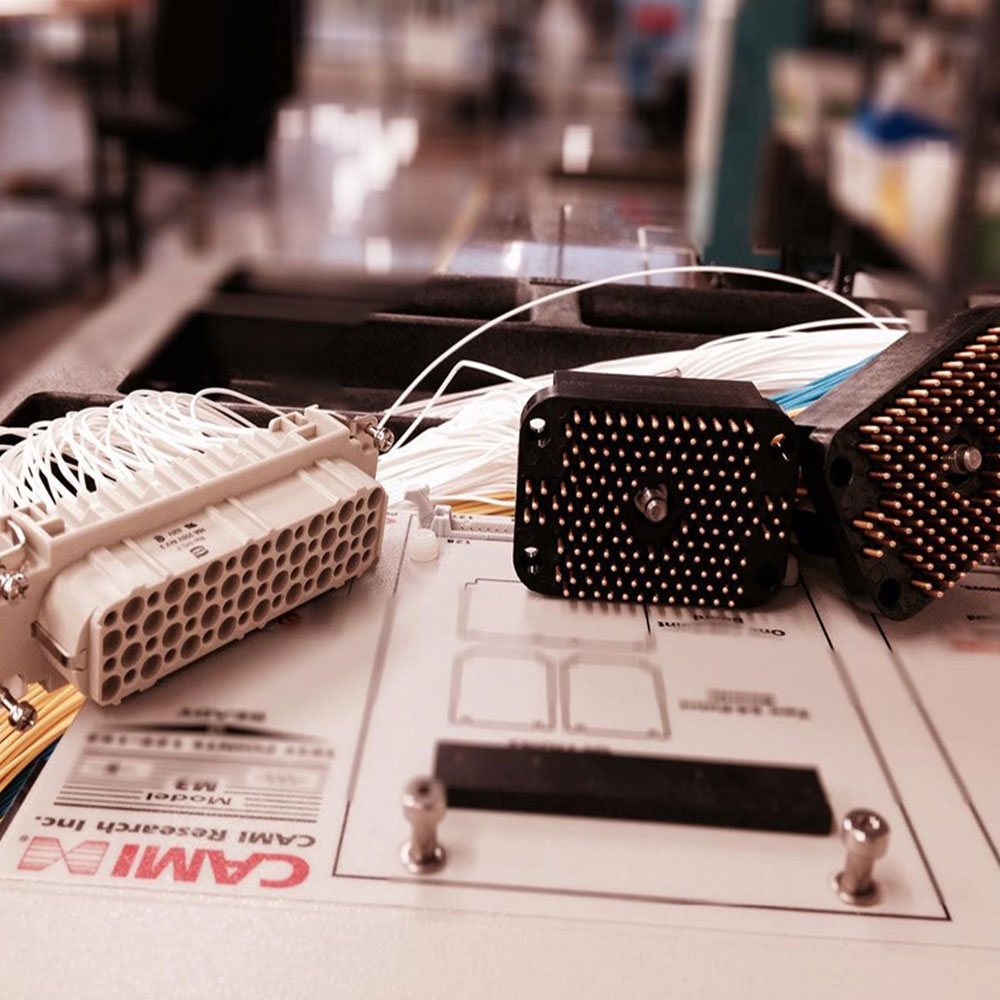

photo credit: Progressive Image

photo credit: AP Technology

"Our production guys find it simple to setup and use. Our clients love it as it provides complete traceability for each and every cable assembly we manufacture."

AP Technology, UK