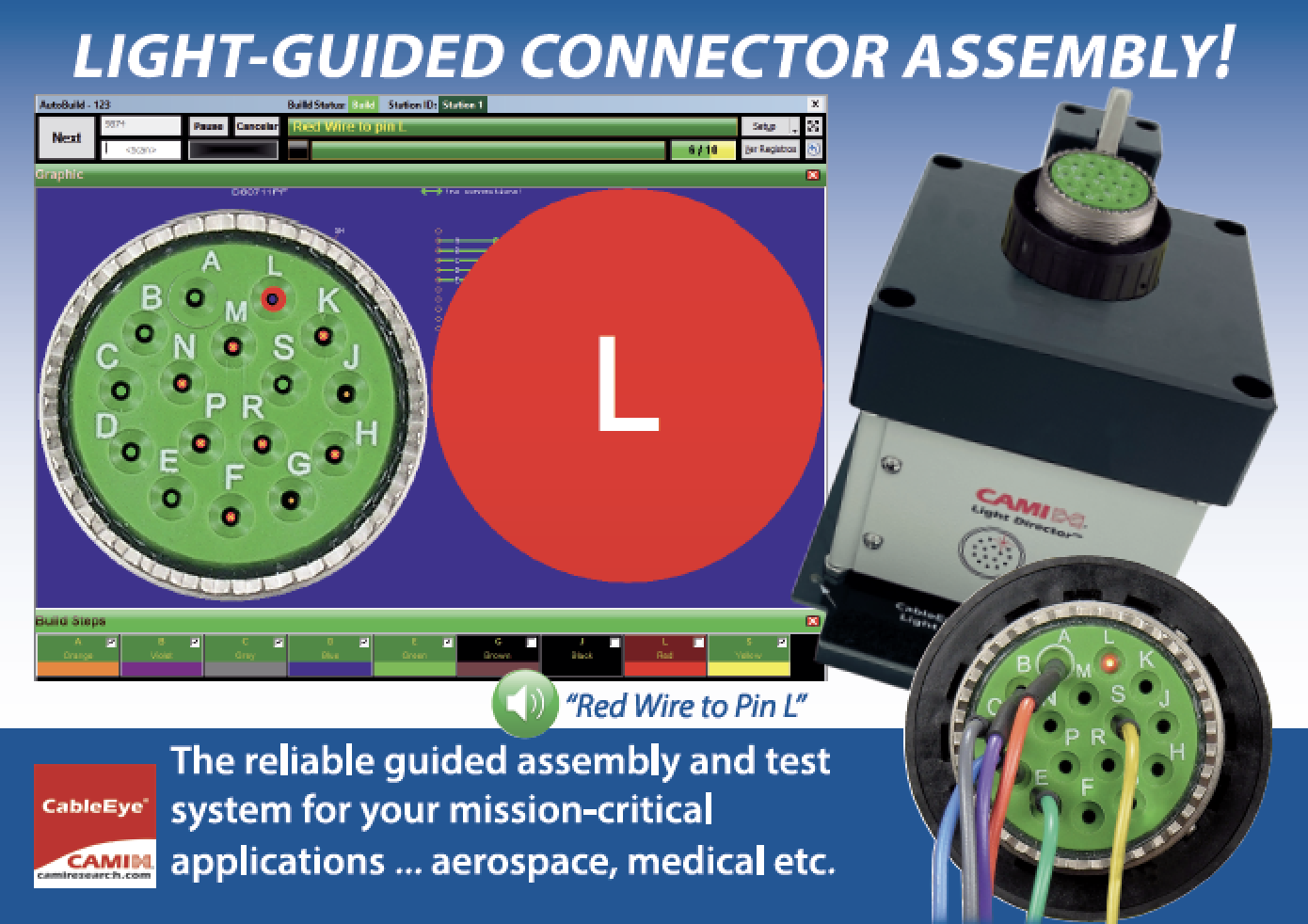

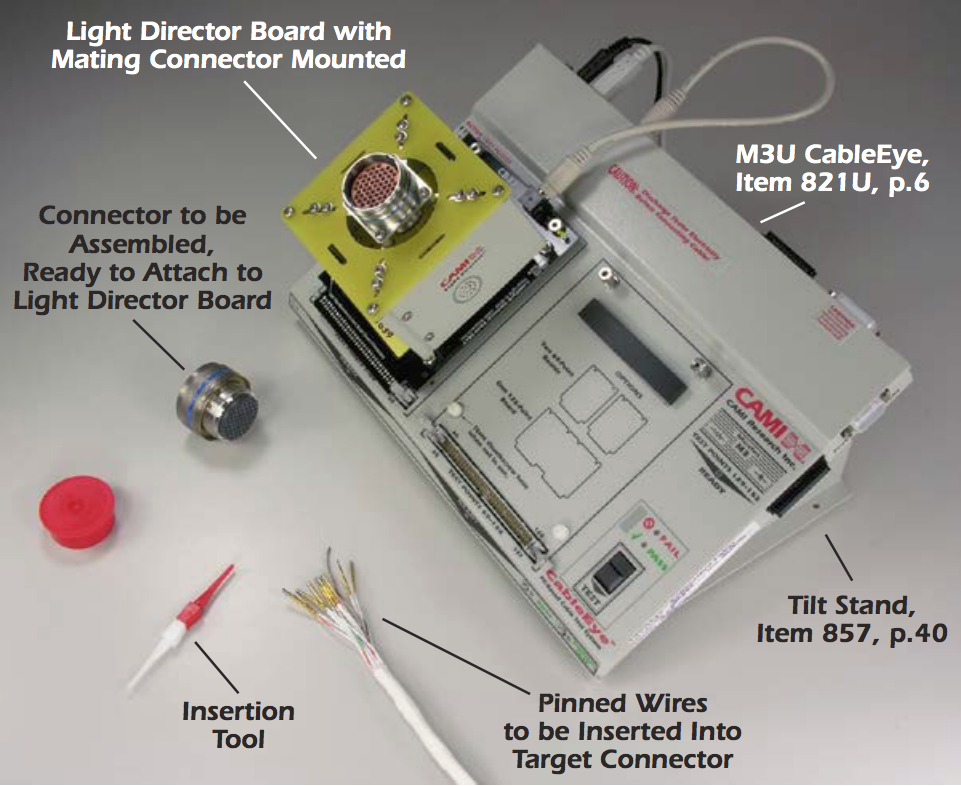

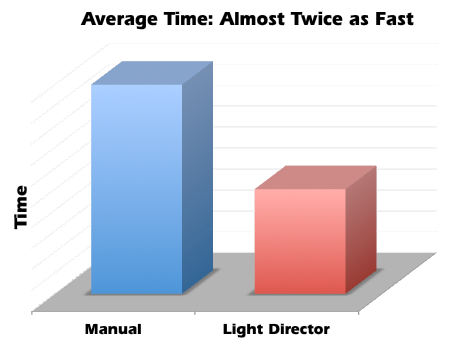

Light Director™ Guided Assembly SystemOur Light Director™ system (patented) provides a computer-guided technique for assembling connectors used in aerospace, medical, and other high-reliability applications. This system uses light fibers and super-bright LEDs to individually illuminate target cavities in the connector being assembled. When the technician enters the wire code printed on unconnected wires, or touches a wire connected at the other end, the CableEye® software turns on the appropriate fiber, thereby causing a bright, flashing light to project from inside the target cavity guiding the technician to the proper insertion point. Correct insertion is confirmed by the elimination of light from that location, whereas insertion into an incorrect location leaves the flashing light visible. Normally, technicians crimp pins on wires in advance of assembly to the connector. Wires may be identified during the assembly process by numeric code, bar code, color code, or if no codes are present, by electrical detection using a wrist-strap if the far end of the cable has already been assembled and can be electrically connected to the system. Field testing has shown that the Light Director guided assembly system doubles assembly rate over manual methods while nearly eliminating errors. Because the Light Director guided assembly accessory significantly reduces the perceptual challenge of manually locating pin cavities in a complex connector, technician fatigue is greatly reduced, permitting a continuous, high productivity rate throughout the work day. The Light Director system is an accessory for all CableEye testers, except M2-Series. Customers purchase a mounting kit for each mating connector consisting of a CableEye tester plug-in board with special LED sockets, LED light fibers, fiber guide boards, a connector support board, and hardware kit. All parts are reusable. Requires the AutoBuild™ Guided Assembly Software (Item 728). Is NOT compatible with M2-series testers. |

|

Synthetic Speech

Using synthetic speech, the Light Director guided assembly system can read the pin number to the technician, further reinforcing the target location. Speech can be activated in English, Spanish, French, German, Chinese, Japanese, Korean, Polish or Turkish when a matching generic voice font has been downloaded.

Speech recognition is also available as an option permitting the technician to read wire codes to the system, thus eliminating the need for a keyboard or monitor.

Interface Fixturing

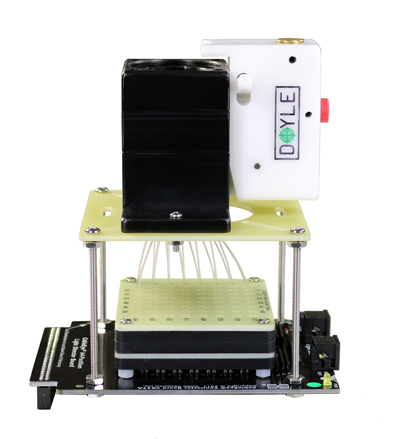

Original Light Director™ Fixture

Our original Light Director guided assembly fixturing uses an actual mating connector as illustrated elsewhere on this page and as appears in the video. The method requires attachment of the build connector to the mating connector on the fixture whether by screwing or pushing one onto the other. We recommend this approach when pin-to-pin centers are spaced by less than 1.5 mm. You will need to supply both the mating connector and a sample build connector if you order this type of fixture.

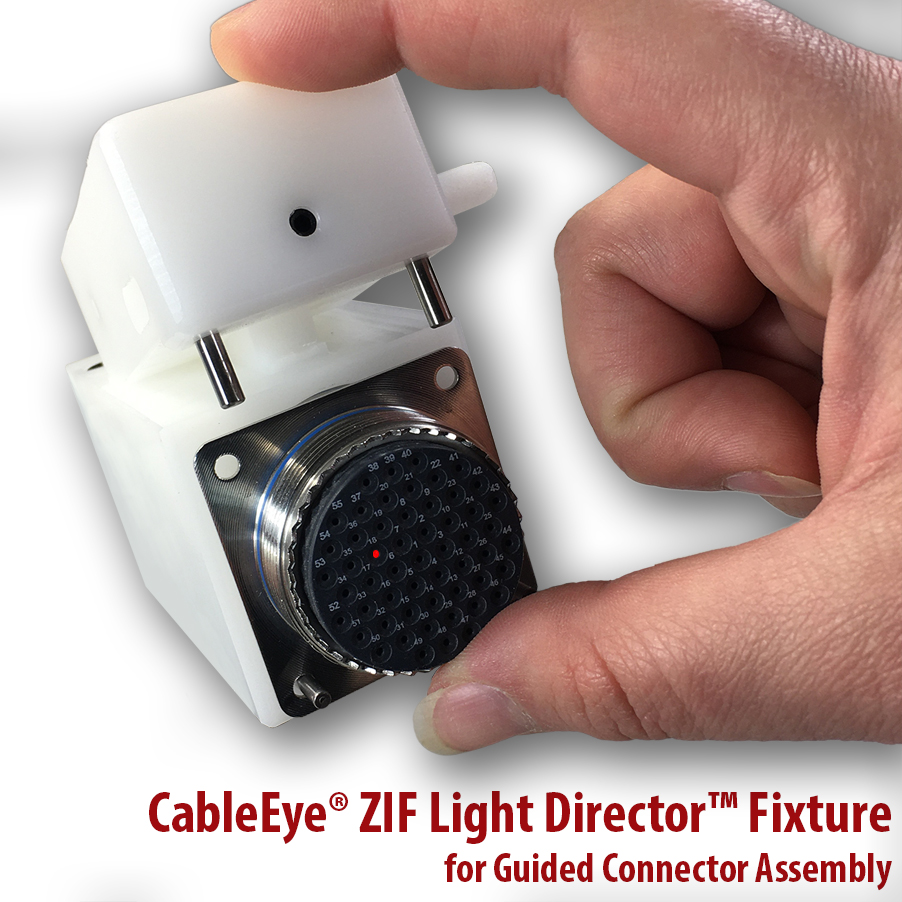

ZIF Light Director Fixture

Since January 2020, each standard Light Director guided assembly demonstration system has been fitted with a Zero Insertion Force (ZIF) fixture subassembly, also referred to as a Light Director ‘head’ or ‘block’ This is our current default Light Director fixture. In addition to presenting an even brighter light to the assembler, it provides easier and more rapid connection and disconnection of the connector being assembled achieving even greater productivity. This type of fixture is available when connector pin-to-pin centers are spaced by 1.5 mm or greater. You will need to send a sample of the build connector if you order this type of fixture.

ZIF Fixture Operation

Simply slide the connector into place - threaded connectors are NOT screwed onto the mating interface. Press the top of the fixture lightly to lock, and the lever to release.

LIF Electrical Test Fixture

A Low Insertion Force (LIF) version of the fixture, also referred to as an electrical test ‘block’, can be ordered for electrical test when connector pin-to-pin centers are spaced by 1.27 mm (0.05") or greater. You will need to send a sample of the build connector with terminals if you order this type of fixture. The two types of fixtures can be placed next to each other so you can assemble first-sided pinning on the Light Director block and then quickly move that connector to the other for electrical connectivity while performing second-sided pinning on the Light Director block. Or you can have them at entirely different stations on the production line.

ZIF/LIF Fixture Manufacturer

Our ZIF Light Director fixtures and LIF, plug and play, CableEye test interface fixtures are manufactured in partnership with Doyle Manufacturing.

Doyle blocks are CNC machined for the highest quality and accuracy and are available with a range of functionality: Pneumatic release lock blocks and electric solenoid release lock blocks for quality assurance; part presence detection for secondary locks, clips, etc.; and step probes and push back switch probes for checking properly seated terminals.

All of these block functions can be monitored and controlled by your CableEye tester out-of-the-box automation capabilities and, if desired, may be supplemented with audible tones, visual tower lights and more. API integration with other equipment is also possible for electrical testing – LabVIEW and .NET libraries are available.

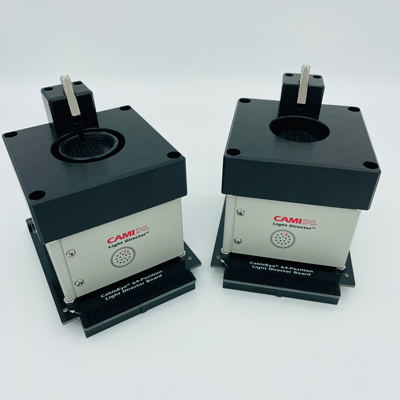

Fully Assembled CB37A and CB38A Light Director™ Boards

Ready to Use

Here you see assembled CB37A boards integrated with ZIF interface fixtures. The first two (top image) were machined for circular 40-pin connectors used in the automotive industry. The third (bottom image) shows a handheld ZIF fixture machined for an Aerospace connector. The connector to be assembled is shown held in place ready for assembly.

Once trained, a technician can assemble and program one of these boards in 60 to 90 minutes, an amount of time that will be earned back during the first day of use in improved productivity. The rugged support structure will be maintenance free, and the mating connector will not wear out because no pins are present (just light fibers which never touch the assembly piece).

When a project ends, you may if you wish easily disassemble the board and reuse all parts for another project. Alternatively, the board may be unplugged from the tester and stored for future use.

Space in front of the board may be used to label this unit either by connector, cable, or customer.

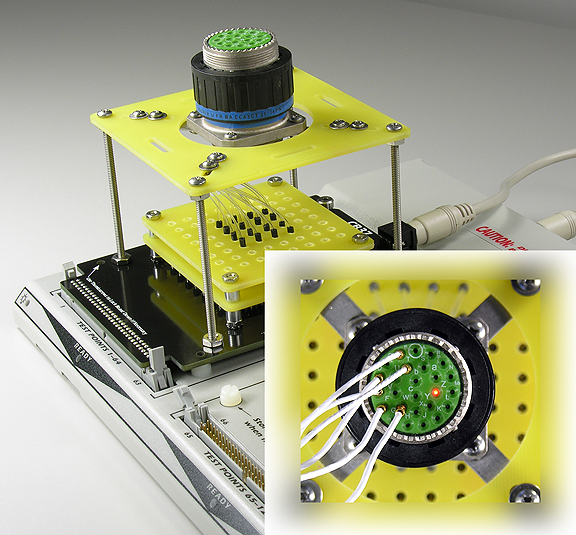

In the next photo, you see a 16-pin mating connector mounted to an assembled CB37A board (original fixturing). This method is required when pin-to-pin centers are spaced by less than 1.5mm.

The CB37A can handle connectors of up to 64-pins. The CB38A board accepts connectors with up to 128 pins.

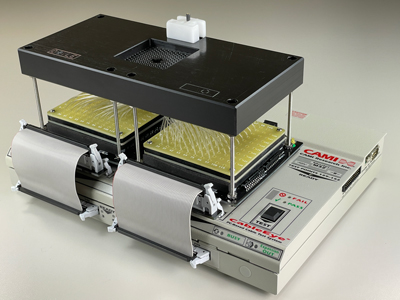

The bottom photo shows a universal ZIF fixture for light-guided assembly of 212p, 158p, and 104p connectors destined for defense application. It is integrated with two Light Director CB38A boards and attached to a 256 TP tester (low voltage system shown).

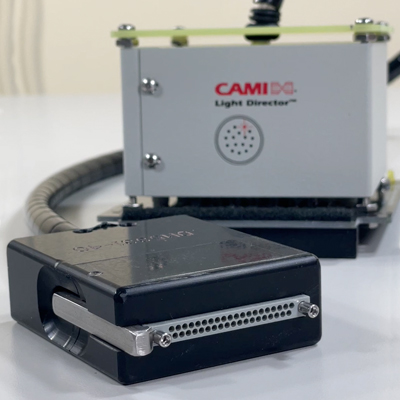

Light Director™ Guided Assembly Setup

In this photo, an assembled CB37A is mounted to the CableEye tester and is ready to use. The connector to be assembled is on the bench along with the pre-pinned wires ready to be inserted. In this case, each wire is numbered to correspond with a printed insertion list.

If assembled manually, the insertion list would tell the technician which cavity number should receive each numbered wire. The technician would then carefully locate the cavity, sometimes counting forward or backward from a reference location, and insert the pin into this cavity. During manual pin insertion, locating the correct cavity takes time and requires the technician’s full concentration.

Using the Light Director system, the technician simply looks for the cavity with a flashing light and inserts the pin there. Neither reading cavity numbers from the target connector nor counting forward or backward from a reference position is necessary.

This reduces the perceptual challenge in finding the target, and therefore speeds assembly, improves accuracy, and reduces the fatigue level that would be experienced after several hours of work.

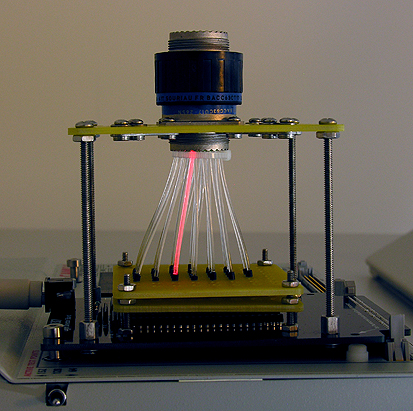

Fiber Routing

Here you see an assembled CB37A (minus shroud to show the fibers) integrated with a ZIF fixture. This ZIF fixture was machined for a circular 16-pin connector and includes an optional probe plate to assist in second-sided pinning.

The light path may be viewed in a dark room. Because the light source is a high-brightness LED but not a laser, the light can be easily seen without any distortion or eye strain. Here you see an assembled CB37A, minus shroud, integrated with customer-supplied mating connector.

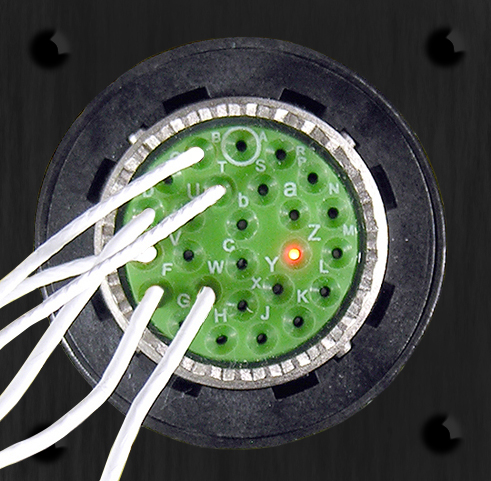

View Into Workpiece During Assembly:

Flashing Cavity Shows Target Pin

The light flashes about five times per second. Flashing helps identify the target cavity in the presence of ambient light and previously inserted wires.

Moisture Plugs

Prior to pin placement, we illuminate all cavities requiring moisture plugs to allow rapid plug insertion. Blocking cavities not requiring pins further reduces the chance for insertion error.

.jpg)

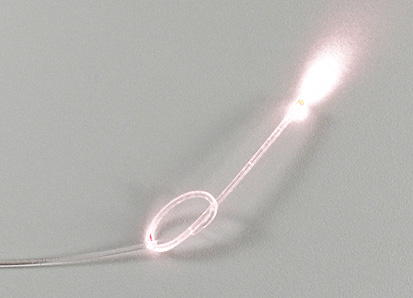

Flexible Light Fibers

Our Rayon™ light fibers flex easily to accommodate widely varied connectors. Longer fibers permit more convenient assembly and readily coil under the connector when the fixture is secured.

The fibers are extremely flexible allowing us to use long fibers to ease assembly and then bend them out of the way when the mounting plate is attached.

.jpg)

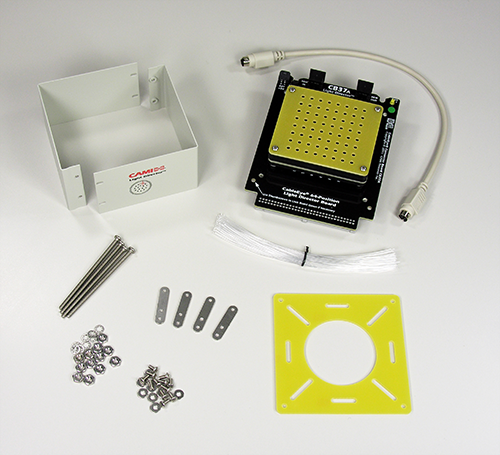

CB37A, CB38A Mounting Kits

Each mounting kit includes an assembled light driver board (CB37A shown below), connector support plate, mounting hardware, light fibers, fiber shroud and power cable. All parts are reusable.

Connector Interface (ZIF Fixture [Item 899C] or build connector) - Not Included.

Assembly and Programming (Items 610/611) - Not Included.

Ready to Build!

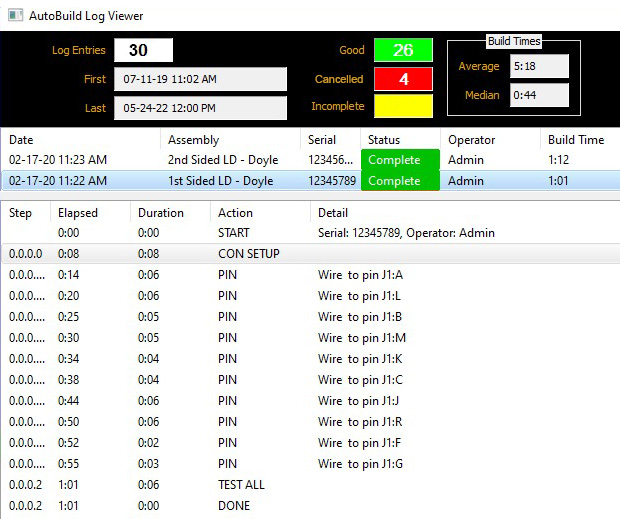

A connector graphic, assembly sequence, and voice prompt support the Light Director guided assembly system in providing backup information for the operator. All insertion steps are logged, so that in the event of power failure or computer malfunction, the build can resume when normal operation is re-established. Additionally, automatic data-logging of build statistics and operator performance occurs.

Light-Guided Connector Assembly: Time & Cost Benefit Studies

Timing Studies (graph) and Cost Benefit Study (download .pdf file) carried out with original style fixturing. Even greater productivity is achieved with the ZIF/LIF fixturing due to easier and more rapid connection and disconnection of the connector being assembled.

... nothing but positive reviews from our Quality department and more importantly from our customers.

We have used our CAMI CableEye test equipment for over three years. We routinely use it to test over 1,000 test points on an aviation harness and have nothing but positive reviews from our Quality department and more importantly from our customers. The reliability of the equipment allows us to provide our customers with the best possible products. We've also found that the customer service and response time from CAMI Research to be excellent. All in all a company I would highly recommend using.

Eric Lutz, VP Production

Galaxy Wire and Cable, Inc.

(Contract Cable Assembly)

Hear more from our customers ...