High Voltage (HiPot)

Cable & Harness Testers

CableEye® HVX, HVX-21

High Voltage (HiPot) Cable Testers

HVX, HVX-21

Includes:

128 Test Points (Expandable) + 24 Accessory Test Points

Standard Operating Software

Probe

Two-Year Product Support Subscription - Renewable

Models:

Item 829, HVX, 1500 Vdc, 1000 Vac, 1 GΩ

Item 829A, HVX-21, 2100 Vdc, 1200 Vac, 5 GΩ

Hardware Options:

Item 828, 128-point Expansion Module for HVX

Item 832, 4-Wire Resistance Measurement, 1 mΩ at 1 A

Item 833, Advanced Measurement (Capacitors, Wire Pair Capacitance, Twisted-Pair Detection, Cable Length Check, 20mΩ Wire Resistance Resolution). Must be ordered at time of purchase of the Control Module.

Item 835, External Measurement Instrument Port

Item 829X, Remote Control Connector

Accessory Options:

Items 738H,759,760H ..., Plug-in Connector Boards

Item 864, Pre-Assembled AMPMODU Cable

Item 765, Relay Control Board (for ext. digital control)

Item 879, Environmental Sensor

Item 877, Protective Cover

Item 755A, 778A/B, Header Isolator ™ Protective Adapters

Item 704C/D, Rolling Pelican Case

Software Options:

Item 708, PinMap ™ Fixture Editor

Item 707, Connector Designer ™ Connector Editor

Item 860, Standalone Software License

Item 709, Exporter Software

Item 730, Win32/.NET API Software License with LabWIEW ™ Interface

Book your Free Trial now!

Next Topic | Previous Topic | TOC

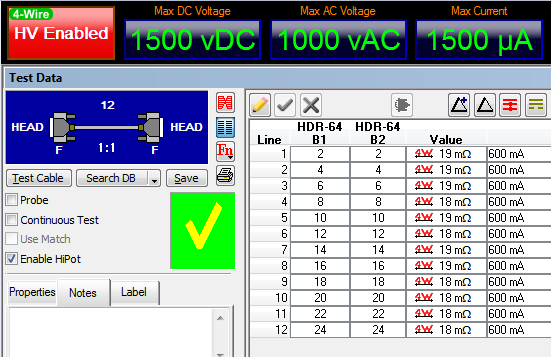

Containing both low voltage and high voltage subsystems, the

automation-ready HVX series permits expanded testing for insulation

resistance, dielectric breakdown, and Zener diode breakdown voltage. Optional Add-Ons provide precision resistance measurement (Items 832, 833), twisted pair checks (Item 833), and

high isolation resistance measurement at very low voltage (Item 825). The Advanced Measurements option provides increased (x5) 2-wire resistance resolution, and the measurement of capacitors, wire pair capacitance, twisted pair testing, length to fault (open/short), and cable length.

Test small cables to large harnesses, backplanes, and complex networks. After checking for opens, shorts, miswires, and resistance limits, the

system applies a user-selectable voltage to each connection group

in the cable - from 10 V to the maximum dc/ac voltage. Ramp Up,

Ramp Down, Dwell Time (Test Time), Trip Current, and Trip Delay

(Soak Time) are adjustable. Leakage Current detected during the high

voltage test phase provides a measure of insulation quality. Insulation

resistance up to 1 GΩ or 5 GΩ may be recorded. Any leakage current

exceeding a preset limit reveals the presence of moisture, flux, or other

contamination on exposed contacts.

Leakage measurements of 10 GΩ isolation at a test voltage of 100 Vdc can be made with the External Measurement Instrument port option.

Low voltage resistance thresholds can be set for contact resistance down to 0.1 Ω, and

for isolation up to 5 MΩ. Measure embedded resistors from 100 Ω to 1 MΩ with 1%

accuracy, and lesser accuracy from 0.1 Ω to 5 MΩ. LV measurement takes less than 0.5 s.

Robust hardware includes: A TEST pushbutton with READY, PASS, and FAIL indicators for one-button operation; Signal remote control and test probe sockets; External Terminals for insulation testing on chassis, panels, and individual components; Industry-standard 64-pin dual-row latch headers for easy interface to external test fixtures of your own design for custom applications; USB Communication; and a rugged, 1/16”-thick aluminum case with scratch-proof Lexan surface for long life in an industrial environment.

Simple in-built scripting permits production-testing automation from test through reports and labelling: Set up pop-up Work Instructions; program optional external relay boards to switch diverter gates, lock & release latches, and more; program READY, PASS & FAIL signals to operate tower lights, LEDs, audible tones, label printers etc.; use optional API & LabView interfaces for integration with other equipment.

HVX series testers allow users to meet industry-standard A620 guidelines. Archival-quality reports show user-selected test parameters such as test voltage, leakage current, and insulation resistance for each wire group, and denote PASS or FAIL.

The system employs numerous measures to ensure operator safety. Each login name must have system administrator authorization to permit enabling of the high voltage function. Once logged in, the operator must confirm awareness of the presence of high voltage by pressing a hardware-enable button for that test session. During testing, a bright red light bar turns on when high voltage is present. If desired, remote test and stop switches are available. Finally, test current that exceeds the maximum 1.5 mA causes an automatic halt of that test and cessation of voltage.

Control Module Price Includes: Expandable 128-point tester; probe; installation drive with software and documentation (Getting Started Guide, Software Introduction, User's Manual); two-year Product Support Subscription inclusive of free software upgrades, tech support and warranty. READY TO USE

Select Add-On Options

Hardware: 4-Wire Measurement, Advanced Measurement, External Meaurement Instrument Port, HV Remote Control, Expansion Modules

Software: AutoBuild™ Guided Assembly, PinMap ™ Fixture Editor, Connector Designer™ Connector Editor, Custom Reporting, Win32/.NET API with LabView™ interface

Accessories: Plug-in Connector Boards, AMPMODU Cables, Foot Pedal, Relay Control Board (for external digital control), Protective Cover, Pelican Carrying Case, Environmental Sensor, Header Isolator™ Protective Adapters

Cable and Harness Manufacturing: CableEye Cable Test and Management System, Q&A

What are the alternatives to the CableEye brand and how do they compare?

Who benefits from using the system?

How does cable and harness testing with a CableEye test system increase productivity?

Can all cables/connectors be tested ...?

How much time can be saved ...?

How much more productive will a user be ...? Read now!

Cable and Harness Manufacturing: Productivity through Flexibility

Learn how to choose a cable & harness tester that remains relevant as product design changes in addition to providing fast, reliable, accurate results. See how it can improve productivity even beyond the production floor. Read now!

Photo: High Voltage Tester with set of optional CB29 connector boards

Universal power input of 100-240 Vac, 50-60 Hz

Control Module 130 W maximum.

Control Module with three expansion modules 175 W maximum.

Compatible with touchscreen PCs including laptops.

Requires two USB channels, and WIN 7 or later

Control Module Weight: 13.5 lbs (6 kG),

Control Module Size: 12.5" wide, 18.5" deep, 3.8" high + 0.23" footpad height

Includes two-year RENEWABLE Product Support Subscription

comprising software and hardware maintenance, technical support, warranty, and more.

Expandable from 128 Test Points in 128-point Increments

| Standard | Add-On Option | |

|---|---|---|

| Continuity | ||

| Opens, Shorts, Miswires | ||

| Intermittent Faults | ||

| Complex Networks, Backplanes | ||

| Resistance | ||

| Connection, non-Connection Quality | ||

| Resistance (2-Wire) | ||

| Continuous Resistance Scan | ||

| Fixture Resistance Nulling | ||

| Resistance (4-Wire Kelvin) | ||

| High Current Resistance | ||

| Capacitance | ||

| Wire Length Cable Length | ||

| Length to Fault (Open/Short) | ||

| Twist Pairing | ||

| Insulation Quality | ||

| Dielectric Strength Dielectric Withstand Voltage (DWV) | ||

| Insulation Resistance/Isolation, Leakage | ||

| Presence of Contaminants | ||

| In-Line Components | ||

| Resistors | ||

Diodes Orientation, Forward Voltage | ||

LEDs Orientation, Color Detection | ||

Zener Diodes Orientation, Forward Voltage, Reverse Breakdown Voltage | ||

Capacitors | ||

| Parts - Single Channel Safety Test (Chassis, Panels, Transformers ...) |

||

| Environmental Data (Temperature, Rel. Humidity, Pressure) |

| TOPIC |

|---|

| Overview |

| Test and Measurement Matrix |

| 4-Wire Measurement |

| Advanced Measurement |

| External Measurement Instrument Port |

| HVX Control Panel |

| External Terminals |

| Rear Panel |

| Expansion Modules |

| HV Remote Control / Deadman Switch |

| Software Control Screen |

| Test Parameters |

| Test Progress Panel |

| Pelican Case |

| Safety & Electromagnetic Compatibility |

Click links above to jump to topic, or just keep scrolling ...

|

Next Topic | Previous Topic | TOC |

4-Wire Measurement

Optional Add-On Item

Measures as Low As 1 mΩ

An add-on option for the CableEye HVX high voltage cable tester that permits expanded testing for contact and wire resistance as low as 1 mΩ. After checking for opens, shorts, miswires, and resistance limits, 4-wire Kelvin measurement applies a user-selectable test current from 10 mA to 1 A to determine connection resistance within 1 mΩ. The resistance profile of a model cable may be stored and used as a basis of comparison during later testing to reveal cold solder joints, faulty crimps, recessed pins, pin contact contamination, improper wire gauge, and stress-extruded wire.

Four-wire measurement eliminates any effect of fixture resistance to obtain a precise value of the unit under test (UUT) resistance only. The same high-accuracy measurement may be obtained with a short fixture attached directly to the tester, or with a large wire harness fixture that may extend a considerable distance to reach the UUT. Users may optionally set up a high-current stress test for wiring by driving up to 1 A of current through each conductor, and setting a dwell time from 100ms to 3 min. Increasing resistance during the dwell period may show problems not detected with a shorter measurement interval.

This option may be purchased with any new HVX tester, or added as an upgrade to any of your existing HVX testers.

Improving Cable Quality & Reliability: Resistance Measurement to Within 1 mΩ

A How-To Guide: Using 4-wire Kelvin measurement technique to improve cable quality & reliability. Read now!

Next Topic | Previous Topic | TOC |

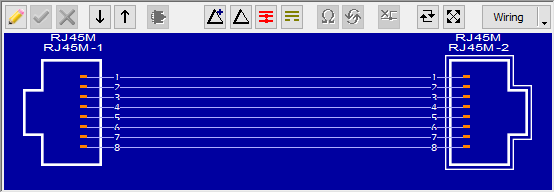

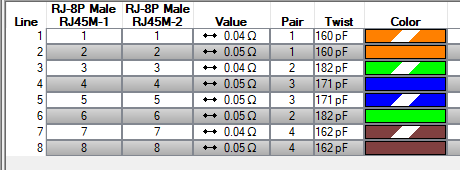

Advanced Measurements

Optional Add-On Item

Capacitors, Wire Pair Capacitance, Twisted-Pair Detection, Cable Length Check, 20mΩ Wire Resistance Resolution

The Advanced Measurements Option provides increased (x5) 2-wire resistance resolution, and the measurement of capacitors, wire pair capacitance, twisted pair testing, and cable length. Refer to specifications for more detail.

This option must be ordered at the time of purchase of the control module. It cannot be added as an upgrade to existing HVX testers.

Verifying Twist Pair Relationships with a Continuity Tester

A How-To Guide: Properly testing twisted pair cables to improve cable quality and reliability. Read now!

Next Topic | Previous Topic | TOC |

External Measurement Instrument Port

Optional Add-On Item

Measure 10 GΩ Isolation at 100 Vdc

Of special interest to customers requiring extremely high isolation resistance measurements at very low voltages, this option permits leakage measurements of 10 GΩ isolation at a test voltage of 100 Vdc. It comprises custom software and a hardware upgrade that allows an external measurement instrument to be used in combination with the HVX’s internal relay-switching matrix and reporting software.

It uses the built-in external terminals of an HVX series

tester to accept stimulus signals from the external source,

and that source’s USB or Serial channel to control it and

read measurement data. Co-requires the 4-Wire Kelvin

Resistance Measurement option (Item 832), and a third

party source meter (Keithley Model 2410). HVX systems that are no more than three years old can be upgraded with Item 835. A 4-Wire Kelvin Resistance Measurement upgrade will be required in addition if the original system is without it. Retrofit fees apply.

Next Topic | Previous Topic | TOC |

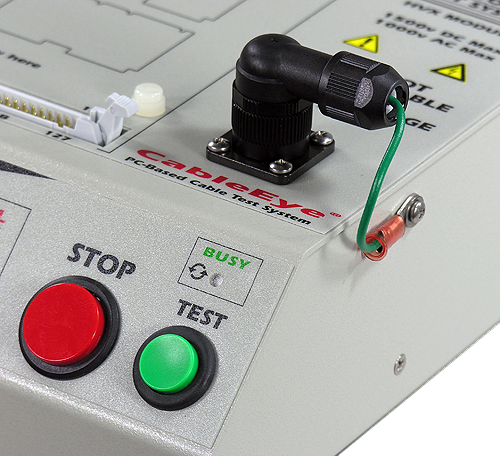

HVX Control Panel

After login, press the HV Enable button (center) to enable the system for high voltage (HiPot) testing. Then, either learn a cable attached to the tester, or load a previously stored cable from the database, and press the TEST button to initiate a test. Repetitive testing can be controlled entirely from this front panel without referring to the computer screen or keyboard. Large, bright Pass and Fail indicators summarize the test result. A large, red High Voltage indicator turns on when high voltage is applied to the test cable.

A fast linear hipot scan checks 13 nets per second. Full DC or AC scans permit adjustable ramp up and ramp down rates, trip current, trip delay (soak time), and test time. Group scan algorithm also available for very fast scanning.

Next Topic | Previous Topic | TOC |

External Terminals

Use these external terminals to perform basic safety testing on chassis, panels, transformers, or other applications requiring a single channel test. The bright red indicator you see to the right of the terminals turns on when you select the external terminals for output. When using the external terminals, the headers normally used to attach connector boards or Ampmodu cables are internally deactivated.

Third party instruments connect to these terminals for the External Measurement Instrument Port add-on option (Item 835) dscribed above.

The external terminals may also be used to easily check the system's voltage accuracy, and for calibration without removal of the cover.

The slot in the lower left corner of the base is the front attachment point for optional high voltage expansion modules that connect to the bottom of the main unit.

The single channel component test control screen is shown.

Next Topic | Previous Topic | TOC |

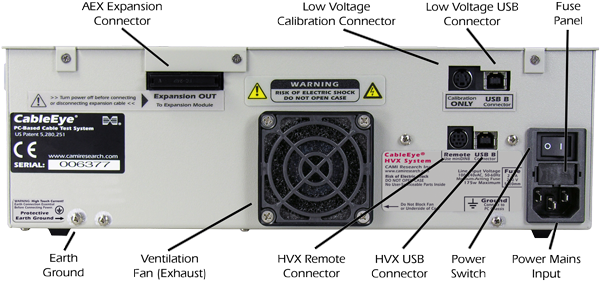

Control Module Rear Panel

Separate USB channels control the low voltage and high voltage circuitry. Both USB cables must be connected. The Remote socket provides access for a footswitch, remote test switch, single-bit relay I/O, and external signals for Pass, Fail, and Ready states, as well as 5 V external power for accessories.

Next Topic | Previous Topic | TOC |

Expansion Modules

Optional Add-On Item

Add test points to an HVX series system with Expansion Modules. This photo shows a 128-point expansion module added to the Control Module. The system can be expanded to 1024 test points by stacking further expansion modules. In this photo, optional CB29 Screw Terminal boards are plugged into the Control Module on the top. You may attach our QuickMount housing to the expansion modules to provide additional board mounting positions, or connect your UUT or test interface fixture directly to the 64 pin headers. Connect your UUT using our stock boards or custom fixtures/panels. Click the button for some ideas.

CableEye Flexible Harness Testers

An overview Click to read.

Next Topic | Previous Topic | TOC |

HV Remote Control / Deadman Switch

Optional Add-On Item

A dummy plug is included that is required for normal control. Replace the dummy plug with an external cable leading to your own controls when remote is used. A matching connector, identical to that shown for dummy plug, is included with this option for wiring to your remote cable.

Next Topic | Previous Topic | TOC |

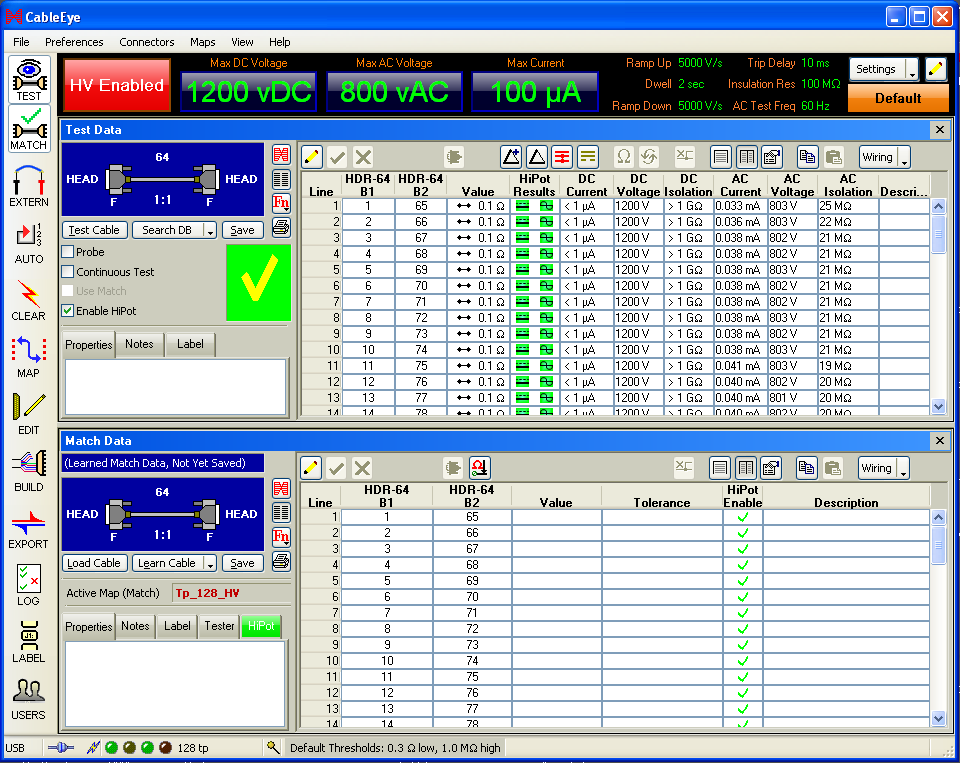

Software Control Screen

An indicator panel at the top of the CableEye control screen shows the present hipot settings. One test cycle can include any combination of a Fast DC Test, Full DC Test, and AC Test. Additional columns may be turned on in the net list to show actual DC voltage, DC current, DC isolation, AC voltage, AC current, and AC isolation. You may test AC at 60 or 50 Hz. Click the button for an overview of the software.

Next Topic | Previous Topic | TOC |

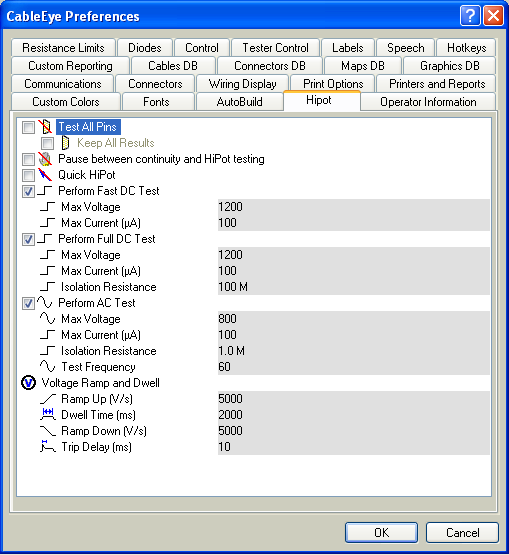

High Voltage (HiPot) Test Parameters

This control screen sets the desired test types, voltages, and limits, and holds default values when you learn or enter a new cable. You may override these default values with custom values unique to that cable and store any changed settings with the cable in the database.

Select the test you wish to perform, and set the voltage and current limits as desired. Test voltage may be adjusted from 10V in 1V increments to the model's maximum voltage: 1500 Vdc and 1000 Vac for HVX, and 2100 Vdc and 1200 Vac for HVX-21.

The current may be adjusted from 5µA (ac/dc) to 3.3mA, and the isolation threshold set up to 1GΩ (HVX), 5GΩ (HVX-21). Choose the lowest trip current possible for cable under test to minimize insulation damage in the event of dielectric failure.

The Ramp times specify how fast the test voltage is reached when starting a test and how fast the cable is discharged when the test finishes. This may be adjusted between 150 V/s to 5000 V/s. Smaller ramp rates are needed for assemblies that exhibit high capacitance.

Choose the test frequency to correspond with the power line frequency under which the cable will be operated.

Electrically Testing Long Cables

Learn how parasitic capacitance can affect your safety and the accuracy of your results when testing cables longer than 10ft. Click to read.

Next Topic | Previous Topic | TOC |

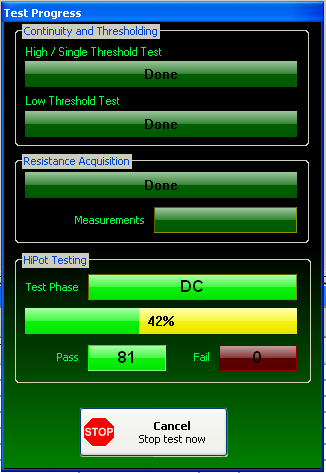

Test Progress Panel

This pop-up window appears on the screen during a test to summarize which test types have been performed, which have been completed, and the progress of the test currently underway. The window disappears when the test is complete, and the final pass/fail count appears in the Test Data window.

Next Topic | Previous Topic | TOC |

Rolling Pelican Case

Optional Add-On Item

For safest storage and transportation.

Custom fit to your system.

SPECIAL OFFER: Buy HVX + Case, get 20% off 1st calibration service. Expires 13m after purchase.

Previous Topic | TOC |

Safety & Electromagnetic Compatibilty

Safety & Electromagnetic Compatibilty

The HVX System has undergone a rigorous series of tests at the Littleton, Massachusetts laboratory of Curtis-Straus, a division of Bureau Veritas, to confirm our product meets the safety and electromagnetic compatibility standards for the CE Mark. This certification is required on any electronic equipment imported into the European Union. In addition to satisfying requirements for the CE mark, customers using the HVX system can feel secure in knowing that this equipment was thoroughly reviewed and tested by engineers in an independent lab and found to meet all applicable standards.

Safety testing ensures that the design complies with regulations governing 120V/240Vac power distribution inside the equipment to adequately protect operators from electric shock under various operating conditions, and that in the event of a component failure or internal electrical short, the system will automatically shut down by fusing or other means, and will not create a fire hazard. Part of this testing involved shock testing. This consisted of dropping a 0.5 kG steel ball from a height of 1 meter onto the case during operation, applying a similar force to the unpowered power jack, and dropping the tester on each corner of the case. Other tests involved placing it in a 97% relative humidity environment to see if internal shorts were created, checking the Lexan labels applied to the case to be sure they did not burn, measuring leakage current from the DC power supplies, and installing 60 temperature probes inside the equipment to monitor internal temperature during operation.

Because of the hazardous voltages produced by this equipment, the lab required additional testing to ensure that, in the event a short developed on the high voltage board, the system would immediately shut down without creating an electric shock or fire hazard. They accomplished this by intentionally introducing a short on the board during high voltage operation and monitoring the response. Also, because our high voltage board uses a custom-designed transformer to generate the AC test voltage, they needed to disassemble one of these transformers to confirm that the firm who built it allowed adequate spacing and insulation.

Electromagnetic compatibility testing ensures that the HVX tester does not emit interfering levels of electrical noise that might affect other equipment, and that the system will not be adversely affected by environmental electrical noise, conducted electrical noise through the power lines, or electrostatic discharge.

To prove that the system did not emit noise above the allowed limit, the test lab placed it in a sealed room and slowly rotated it in front of a sensitive antenna while it performed a high voltage test. Immunity testing involved focusing a radio beam at the unit, also on a rotating table, while a transmitter swept through a wide range of frequencies as the unit was performing a high voltage test. The unit must run its test to completion without interruption to pass this test.

Electrostatic discharge (ESD) testing posed the greatest risk to the equipment. For this test, the test lab used a special ESD simulator "gun" to apply +/– 4kV discharges to the case, switches, control panel, USB cable, and other places all over the equipment while the HVX performed a test to confirm that the system would not stop functioning given these environmental insults.

CableEye® Testers: Environmental, EMC, & Safety Specifications

A reference document. Click to read.

CE Mark: EU Declaration of Conformity

A reference document. Click to read.

Previous Topic | TOC |

Quicklinks:

Software Introduction Guide

A step-by-step explanation of how CableEye software works.

CableEye Unique Benefits

An illustrated presentation of how a CableEye cable and harness test system can help you.

Product Selection Wizard

Select your optimal test system in just seconds.

Technical Specifications

Compare, contrast, and plan for future growth.

Videoclip Demonstrations

See how easy it is to design, test, assemble, data log, report, label, and automate.

Hands-on Demo

Borrow a demo unit and take it for a test drive.

Product Catalog (html)

Specifications and part numbers for every item.