Build Cables and Harnesses Using Guided Assembly with our AutoBuild™ Software

- Use Supplied Probe or Wrist Strap to Touch Wire for Connection Instructions

- Test-as-you-Build to Catch Problems the Moment they Occur

- Place Wires, Resistors, and Diodes

- Optional Speech Instructions Eliminate Need to View Screen

- Increase assembly rate

- Increase assembly accuracy

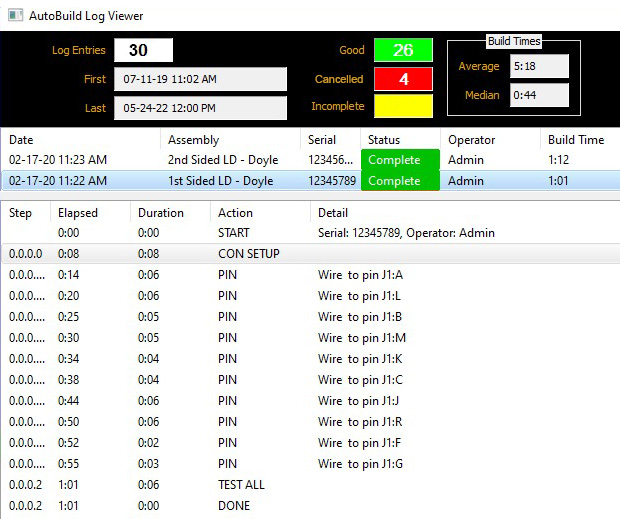

- Automatic data-logging of build statistics and operator performance.

- Automatic logging of all insertion steps so that in the event of power failure or computer malfunction, the build can resume when normal operation is re-established.

- Use with our Light Director™ System (Item 767) for Guided Connector Assembly

Our optional, add-on AutoBuild™ software (Item 728) offers Guided Assembly for cables and wire harnesses. Use a supplied probe, or a finger with wriststrap, to touch an unterminated wire (see photo below) and the software shows exactly where the wire should be connected (see screen image below). As the operator attaches each new wire, the AutoBuild guided assembly software checks the entire assembly and provides a clear checklist showing all completed good connections. Build statistics are ato-logged. All insertion steps are logged in the event of power failure or computer malfunction, so that the build can resume when a normal operation status is re-established.

When using our resistance-capable testers, you may connect diodes and resistors by name and value, check resistance values over the tester's specified range, and test conduction and isolation resistance against specified thresholds. Programmable tones accompany the graphic screen to give clear signals to the operator when good connections are completed or when incorrect connections, resistance violations, or diode insertions are detected.

Image Index

Touch Wire to Obtain Connection Instructions

Screen Image Showing Instructions

Screen Image Showing Log Report/Build Statistics

Light Director™ System Flashes Light in Target

Next | Back

Next | Back

Back

Handheld ZIF Light Director Fixture

Board-Mounted Configurations Available